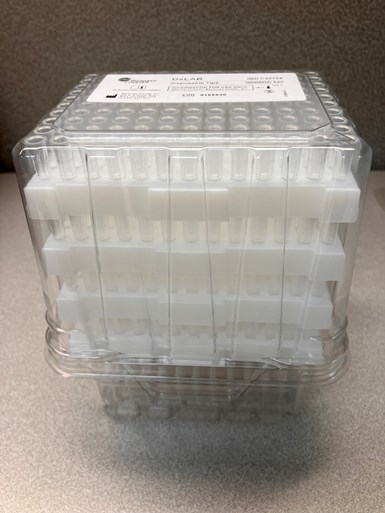

This custom thermoformed package can hold and protect 520 pipette tips in four rigid polystyrene trays. Photo Credit: Beckman Coulter

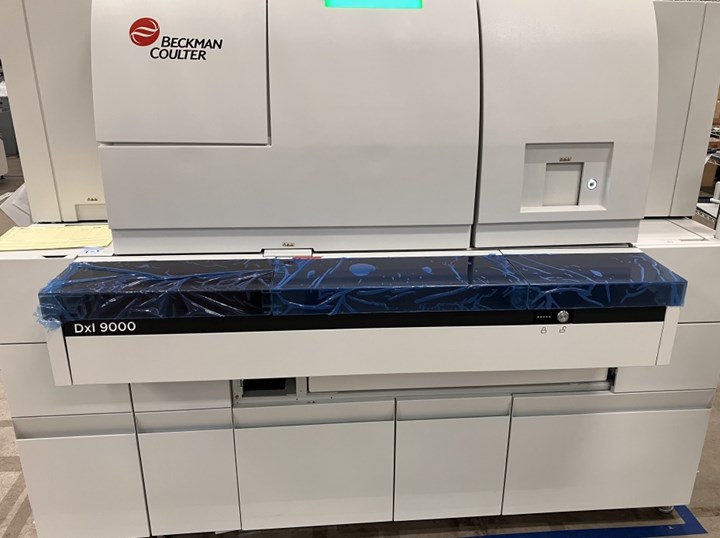

Beckman Coulter Diagnostics, a global company in clinical diagnostics, unveiled its DxI9000 Access Immunoassay (IA) analyzer in May 2023. This next-generation analyzer addresses clinical laboratories’ need for analytical speed, reliability, reproducibility, quality and menu expansion.

Everything on this new instrument was engineered with the most advanced technologies to maximize performance and optimize resources, including the packaging of the DxI 9000 analyzer’s related consumable products.

A critical, single-use consumable product for the DxI 9000 analyzer is the highly sensitive polypropylene (PP) pipette tip. This pipette collects a patient’s sample from a test tube and dispenses it into the analyzer. This step requires pipettes to remain undamaged to ensure the quality of the analysis.

The Beckman Coulter Diagnostics’ Global Plastics team needed a packaging solution seamlessly integrated with the DxI 9000 IA analyzer, minimizing material content and capitalizing on recycling opportunities. Beckman Coulter approached Plastic Ingenuity to partner on designing a custom thermoformed package to hold and protect 520 pipette tips in four rigid polystyrene trays.

Overcoming the Design Challenge

The thermoforming process differs from the injection molding process. It is a manufacturing process where a plastic sheet or film is heated in an oven to a high enough temperature so that it can be stretched into a mold that is formed and cooled to a specific finished shape in a mold (or die) and trimmed to create a usable product. Thin gauge thermoforming is primarily used to manufacture containers, lids, trays, blisters and clamshells for the food, medical and general retail industries. To protect the highly sensitive pipette tips from handling damage, Plastic Ingenuity designed a unique cover and base tray to be as robust as possible yet remain a viable thermoformed PET part.

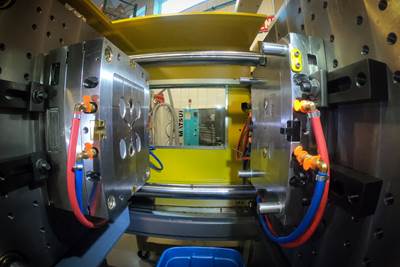

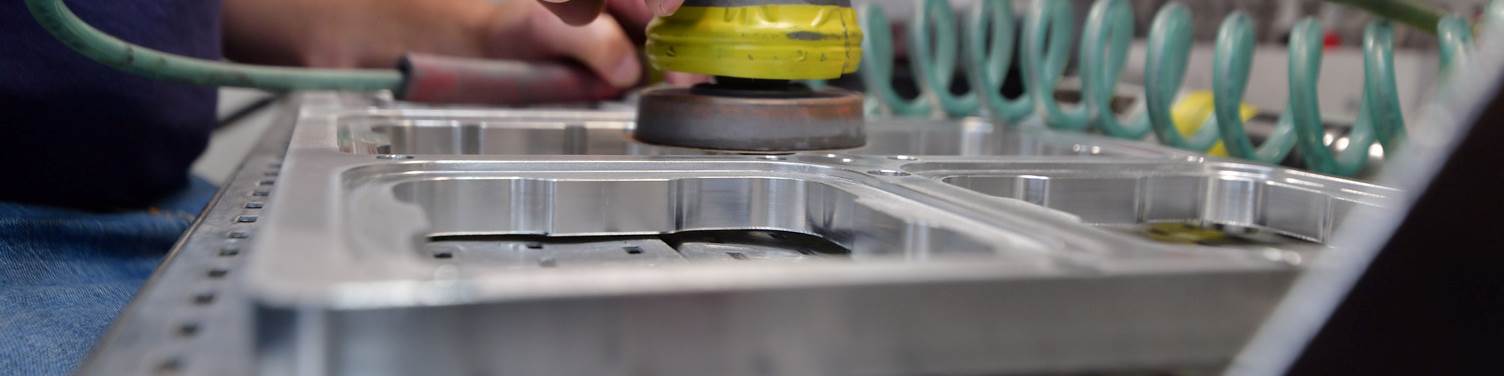

Production thermoforming mold being polished. Photo Credit: Plastic Ingenuity

First, a prototype tool was built for the initial fit, form and functionality trials. To optimize the design, and instead of simply adding material, Plastic Ingenuity initiated a design for manufacturing (DFM) approach. It focused on design features such as adding ribs, flutes and structure to both the cover and base trays that increased overall package strength without compromising the design intent. Subsequently, a production thermoforming tool was designed and built for production purposes, incorporating lessons learned from the prototype tool.

To optimize the design, Plastic Ingenuity focused on design features such as adding ribs, flutes and structure to both the cover and base trays that increased overall package strength without compromising the design intent.

After discussions with Beckman Coulter’s Global Plastics team, the Plastic Ingenuity team incorporated a cut-out feature to the package’s base tray, enabling laboratory techs and operators to easily reach inside the package when loading the individual pipette trays into the instrument. These design and process improvements resulted in successful test results and the passing of the thermoformed mold validation requirements (the IQ/OQ/PQ phases).

Recycling of PET Packaging Material

#1 Resin ID Code for PET found at the top corner of the cover. Photo Credit: Beckman Coulter

PET is the most widely used and recycled packaging material in the world. It serves to protect its contents and is lightweight, with optimized clarity and chemical resistance/wear properties. The best part about PET plastic is that it can be recycled into the production of new PET packaging and other products such as PET bottles.

This specific application uses reground PET material for the thermoformed packaging of the consumables used in the DxI 9000 IA analyzer and suits the environmental sustainability strategy to recycle and reduce waste generation. The #1 Resin ID Code for PET is at the top corner of the cover of the package.

The latest Beckman Coulter Diagnostics DxI9000 Access Immunoassay (IA) analyzer addresses clinical laboratories’ need for analytical speed, reliability, reproducibility, quality and menu expansion when identifying and detecting the concentration of specific substances in a sample during a variety of medical testing. Photo Credit: Beckman Coulter

The design improvements to the DxI 9000 analyzer pipette kit packaging unit offered material savings of 58% less plastic when compared to traditional molding methods. Additionally, the tooling improvements enhanced the packaging material efficiency, and the Beckman Coulter team achieved its product protection, material handling and design for recycling goals.

Related Content

Compact Stack Mold for Thin-Wall Packaging

Oerlikon HRSflow says the patent-pending design allows the use of smaller injection molding machines while still promising the high output a stack mold tool.

Read MoreR&D Drives Innovation and Problem-Solving at Michigan Blow Mold Builder

Mid-America Machining focuses on reshaping designs, “right weight" initiatives, continuous improvement and process refinement to enhance moldmaking efficiency.

Read MoreCompact Robotic Palletizer Easily Automates Packaging Process

The Cube cell, complete with a KUKA KR50-R2500 robot, is targeted for small- and medium-sized businesses looking to automate the palletization of their end product.

Read MoreInjection Molds and Integrated Solutions Through Ambition and Innovation

Jordan Robertson, VP, Business Development and Marketing for StackTeck discusses various mold technologies to improve efficiencies in automation, cooling, lightweighting and sustainability.

Read MoreRead Next

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

Read MoreWhat to Look for in Aluminum Mold Alloys

The importance of strength, anodization, weldability, machinability, flatness and porosity to aluminum injection and thermoform molds.

Read MoreA Cooperative Spirit and Uncommon Service: Baumann Tool & Die

With a philosophy of ‘being there for the life of the tool,’ Baumann Tool & Die offers molders a host of design, production and maintenance services to extend tool life.

Read More

.jpg;maxWidth=300;quality=90)