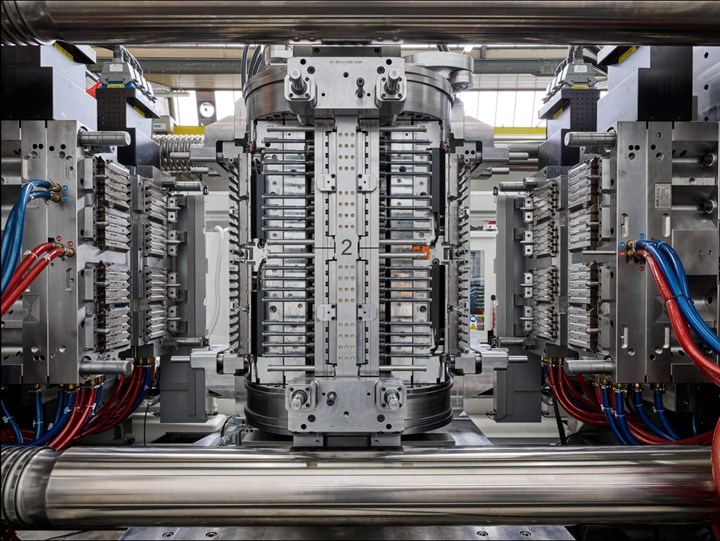

Boucherie specializes in mold manufacturing for small, difficult-to-make parts — multi-cavity, single-component and multicomponent index plates, linear transfer or rotary table stack molds, Flexi Cube and other patented designs. Photo Credit: Boucherie

Who is Boucherie?

John Williams, president, Boucherie USA: Founded in 1928, Boucherie is a fourth-generation family-owned business manufacturing brush-making machinery. Our mold division initially began in 1961 to support the brush block transition from wood to plastic. The company now comprises 300-plus craftsmen, focusing on engineering, innovation and reliability as a partner for precision molds in the consumer, technical and medical industries. Most of our workers are lifelong employees, starting early in their careers and working through retirement from Boucherie. We have two divisions: machine building (brush bristling machines and automation) and our mold division. Machine tool assets are used across divisions.

All development, parts, moldmaking, assembly and testing are completed in-house using precise, state-of-the-art technology and high-quality materials. We specialize in mold manufacturing for small, difficult-to-make parts — multi-cavity, single-component and multicomponent index plates, linear transfer or rotary table stack molds, Flexi Cube and other patented designs.

Over the years, Boucherie has gained in-depth expertise in the construction of molds for all kinds of personal, oral care, medical parts, etc., such as two-material syringe plungers, syringe barrels, Y connectors, iso hubs, toothbrushes, razors, screwdriver handles, etc. Our primary focus is on parts requiring very high tolerance, high-cavitation, single- and multi-material tools.

What is Boucherie’s chief competitive advantage?

Williams: Boucherie’s lifeblood is innovation, developing new mold, machinery and automation technologies in a dedicated R&D facility. In addition to providing the best tooling available, we pride ourselves on technical support before and after the sale. All purchased materials, steels, hot runners and more are of the highest quality available.

All development, parts, moldmaking, assembly and testing are completed in-house.

We provide product design for manufacture (DFM) support and mold flow analysis as appropriate to simplify part and mold design. As an example, with minor customer-perceivable part modifications, we are able to manufacture a three-component part in two cavity sets. A team of engineers closely looks into every new mold project. For complex or multicomponent products, a prototyping program is often desirable, and one or more prototyping molds can be built. After the prototyping phase, our engineering team takes care of the design of the production molds.

Cavities and cores are carefully assembled into the frame. Mold actions, such as slides, lifters, interlocks, mating surfaces and indexing mechanisms, are meticulously checked before the mold is put into the press for a test run. We always test tooling on our own or the customer's injection machines in our shop to help simplify and accelerate installation, operational and performance qualification (IQ/OQ/PQ).

Our mold testing area is equipped with several single-component, bicomponent and tricomponent injection molding machines, ranging from 250 to 5,000 kilonewtons (injection units are available in L, vertical and piggyback configurations). Each machine is housed in a separate room, each of which is closed from an outside view to ensure product confidentially. For turnkey projects, a separate area is available where new molds can be tested and accepted on injection molding machines, sent to Boucherie by the customer.

We do not skimp anywhere in the tooling process, from robust design to materials to tolerancing and expert assembly. The entire process is monitored from request for quoting (RFQ) to validation according to our quality procedures, following ISO9001-15 requirements.

Boucherie has developed a unique, patented Flexi Cube mold technology that enables significantly shorter transfer times between cavities since only the parts are moved from cavity set to cavity set instead of rotating the complete center section of the mold.

What is your latest technology investment?

Williams: Boucherie has continued to invest in state-of-the-art moldmaking technology over the years. Our latest addition is a fully automated EDM line where several EDM machines are coordinated by a single linear robot, enabling the continuous production of electrodes and a 3D measuring system to verify the dimensions/quality of the electrodes.

We are also integrating a high-speed milling machine to add functionality to this line, combining EDM and high-speed milling capabilities.

Boucherie has gained in-depth expertise in the construction of molds for all kinds of personal, oral care and medical parts.

Provide an example of the most significant change to your general approach to business.

Williams: Our overall business approach has stayed consistent over the years. We produce the highest quality molds (SPI class 101 or better), focusing on tooling for difficult-to-manufacture plastic parts. We also relentlessly innovate patented manufacturing methods, like our Flexi Cube molds, to remain a leader in our field and advance technology.

We continue to provide best-in-class before and after-sale service, proactively following up with customers to address any concerns. We treat every program and customer with the utmost professionalism and care and have fun along the way!

The Boucherie team carefully assembles cavities and cores into the frame and meticulously checks mold actions before putting the mold into the press for a test run.

What is the most significant way you expect your business to evolve in the next 3-5 years?

Williams: Boucherie’s mold business historically serviced the brush and toothbrush-making business. Over the years, our moldmaking has expanded to other consumer, technical, pharmaceutical and medical parts. Based on our current RFQs, our business growth, pharmaceutical and medical moldmaking will continue to be the largest segment for which Boucherie provides molds and tooling.

How are you finding and attracting new employees?

Williams: Boucherie recruits new and young talent locally in the greater Izegem (Belgium) area. We recruit from the local technical schools for our internship and apprentice programs, giving this young talent exposure to all aspects of the mold building process.

Describe your most notable mold technology.

Williams: Boucherie has developed a unique, patented Flexi Cube mold technology. This technology is perfect for high-volume multishot parts, such as razor handles, pens and medical devices, to eliminate downstream assembly operations. It enables significantly shorter transfer times between cavities since only the parts are moved from cavity set to cavity set instead of rotating the complete center section of the mold. This mold configuration also allows for multiple shots on each mold face, insert molding, parts requiring multishot plastic on all sides, robotic demolding while the mold is closed and more. The motions in the mold are completely servo-driven and can accommodate differing centers between cavities, moving the parts from cavity set to cavity set around a stationary central cube.

The entire moldmaking process is monitored from RFQ to validation according to quality procedures, following ISO9001-15 requirements.

The core of this mold is a stack design with a central stationary cube around which various stations are provided. The molded parts are held on carriers while traveling on a track around the central cube. These carriers are moved using servomotors, allowing them to travel different distances. As such, the number of stations, their positions and their function can be selected as needed. This results in maximum mold layout flexibility.

Versions for four or more components can be built with or without intermediate cooling stations between injection stations where desired or further with one or more ejection stations or positions where premade structures can be inserted.

Simpler applications include two-component molding, with maximum cavitation in a stack configuration or combined with any extra functions. Because the central cube is stationary, the interface with the injection molding machine can be kept simple. It is comparable to a regular stack mold.

The stationary central part also allows an easy and ample supply of cooling water, compressed air, electrics and so on without the need for delicate rotating couplings. Our in-house specialists realize all necessary motion controls for the servomotors and come in a separate control box with the mold as one fully integrated package.

This technology completely lives up to its name, Flexi Cube, as it can be easily configured to the part design and customer needs. It is truly unique in the industry.

Related Content

Cross Training, In-House Capabilities and Collaborative Design Move Helm Tool Forward

Cross-training, bringing it all in-house, molding and collaborative design are essential to Helm Tool's success.

Read MoreR&D Drives Innovation and Problem-Solving at Michigan Blow Mold Builder

Mid-America Machining focuses on reshaping designs, “right weight" initiatives, continuous improvement and process refinement to enhance moldmaking efficiency.

Read MoreInnovation, Diversification and Integration Guide Mold Builder Growth

Quality Tool and Die team discusses the journey from a small automotive tool shop to a diversified full-service moldmaking and plastic production facility.

Read MorePennsylvania Mold Builder Doubles Footprint, Maintains Quality and Company Values

Quality Mold Inc. doubles its manufacturing footprint but maintains its private company values and structure, delivering quality and fast turnaround from mold design and build through sampling.

Read MoreRead Next

Cross Training, In-House Capabilities and Collaborative Design Move Helm Tool Forward

Cross-training, bringing it all in-house, molding and collaborative design are essential to Helm Tool's success.

Read MoreFlexible Moldmaking

An innovative approach to multi-component injection molding can be seen in a “Flexi-Cube” mold--the first mold of this type was delivered for a 3-component handle in a 24-cavity layout. Here is a glimpse of this particular 5-station mold.

Read MoreCombining Innovation and Artistry to Build Complex, Precision, Multi-Cavity Molds

This Florida mold builder is about high-performance, high-precision moldmaking by blending craftsmanship with technology.

Read More