Electroform and Hononegah High School Partner for Hands-On Moldmaking Education

Electroform teamed up with Hononegah High School to give engineering and manufacturing students a hands-on moldmaking experience — including the design process, machining of components, assembly and mold sampling.

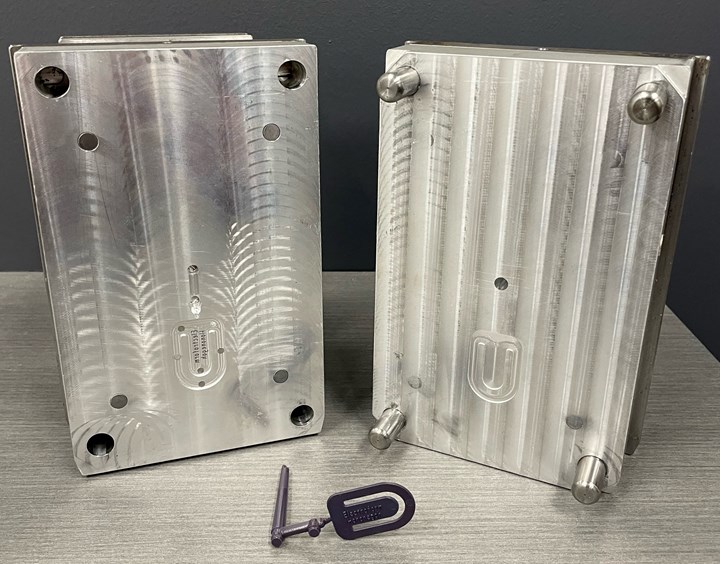

Hononegah Community High School (HCHS) students designed and built injection molds for a simple part Electroform came up with to introduce moldmaking to the class: a paperclip. Photo Credit, all images: Electroform

Even though manufacturing continues to face the skills gap challenge and it remains the topic of conversation at most industry events, we never tire of hearing and sharing another success story of a shop bringing a young, new moldmaking professional into the workforce!

In recent years, there has been a concerted effort to bridge the gap between the industrial sector and education institutions to address the skilled labor shortage. This collaboration aims to prepare students for careers in fields that are in high demand while meeting the needs of industries that require a skilled workforce.

Electroform not only provided the necessary support and guidance but also served as a bridge between classroom learning and practical application.

This time, it’s Rockford, Illinois-based mold builder Electroform partnering with Hononegah Education Manufacturing Connection (EMC) to promote manufacturing, but more specifically, moldmaking and molding, by providing real-world, hands-on experience in manufacturing and engineering. EMC was formed 2 years ago to form partnerships between high schools and regional manufacturing businesses that connect local manufacturing companies in the stateline area with Hononegah Community High School (HCHS) students who are evaluating their career choices. To date, Electroform is the only active mold building participant.

Zach Clark is a design engineer at Electroform and serves as technical support on this outreach project with Hononegah HS and engages directly with the instructor and classroom activities. He was 4 years old and sweeping floors, so officially, he has been an Electroform employee for 4 years. His passion for moldmaking has grown over the years, but it was not there at the beginning. He was more interested in business. “I attended a 4-year college to earn a business degree but then backed up and reconsidered a career. Manufacturing really sparked a fire in me that I’m ready to spread to the next generation,” Clark says.

His father, Wade, approached Hononegah instructor Liz McLevige during a community career fair to join forces on a student moldmaking project as part of the curriculum. McLevige teaches advanced pre-engineering courses and is in charge of the CNC machining classes that would ultimately be integrated into the EMC program.

McLevige’s plastics background made it easy for her to envision a project for the class to work on with Electroform. Eight students, from sophomores to seniors, make up the CAD and machining classes. As part of the program, students have access to a range of equipment and learn skills such as CNC machining, CAD/CAM and robotics.

The first project involved designing and building injection molds for a simple part Electroform came up with to introduce moldmaking to the ECM class: the everyday paperclip. This project enabled the students to dive into the world of moldmaking, CNC machining and practical manufacturing processes. It was a major step for the school and EMC, marking their entry into the world of mold building, a more complex and demanding field.

McLevige initially had reservations about taking on such a challenging project. Her experience as a former project engineer in an injection molding business made her aware of the complexities involved that would present a significant learning curve for both the students and faculty, namely the intricacies of moldmaking and the intense timetable.

However, McLevige recognized the incredible learning potential of this project and the direct connection between classroom learning and real-world applications. The opportunity to create a mold that would produce tangible consumer products, such as paperclips, served as a motivating factor for students and teachers. The students had a chance to see the immediate outcomes of their work, which, in turn, motivated them to take on the challenge — with some students even working overtime!

Electroform not only provided the necessary support and guidance but also served as a bridge between classroom learning and practical application. Clark worked closely with McLevige and the students throughout the project, offering expertise and advice on the moldmaking process.

The students experienced firsthand the importance of precision in moldmaking and the benefits of identifying and correcting mistakes.

It was a learning journey for everyone involved. The high school students had to grapple with challenging aspects of moldmaking, such as creating precise dimensions, ensuring accurate CNC machining and learning the intricacies of injection molding. It required a deep understanding of geometry, material properties and engineering principles. This real-world application of classroom knowledge was an eye-opener for many students, demonstrating the significance of precision and attention to detail in manufacturing.

The project included trips to Electroform’s facility, during which the students witnessed the injection molding process and how their molds played a crucial role in producing the final product — the paper clip.

The outcome of this project went beyond the production of paper clips. It empowered students with a deep understanding of manufacturing and a sense of pride in their accomplishments. “As a result, a few students are interested in a formal apprenticeship,” McLevige says.

The students not only gained valuable knowledge but also witnessed the benefits of identifying and correcting mistakes in the manufacturing process and the importance of precision in moldmaking. Students discovered that the smallest errors in dimensions, tolerances or toolpath calculations could lead to issues in the final product.

What made this collaboration even more impactful was the commitment to continued improvement. Clark and McLevige understood the importance of refining the curriculum to align with the realities of moldmaking. Lessons learned from the initial project informed their approach to future projects, namely adding more time to the schedule to get the project done right.

“Liz has gained much respect with the students due to her efforts, which in turn leads them to respect Electroform’s efforts,” Clark says.

The collaboration between Hononegah HS and Electroform was a clear success. Students were exposed to a dynamic, fast-paced industry and learned valuable skills. The experience also generated enthusiasm for future endeavors, with the number of students participating in the program increasing significantly — growing from eight to 17 students!

This growth underscores the students’ eagerness to explore careers in the manufacturing and engineering sectors, demonstrating that hands-on learning, like the Electroform project, is an effective way to inspire and prepare the next generation of skilled workers.

Related Content

Eden Tool and Eden Manufacturing: A Story of Resilience, Growth and Innovation

This critical parts manufacturer, founded on solid tooling fundamentals, didn’t get derailed with the unexpected passing of the owner because leadership was already building a solid business, not just a good tool shop. Here’s how they managed change incrementally… and they’re not finished yet.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreMold Maintenance Continues to Matter: Enhanced Training Program in a New Facility

I attended a MoldTrax mold maintenance workshop in 2019 and shared my experiences, and despite changes in ownership, the workshop's remarkable value endures, as discussed in a recent Q&A with the current leadership.

Read MoreRead Next

VIDEO: How to Create an Elite Moldmaking Workforce

Alex Beaumont, Vice President of Beaumont Technologies, shares details about the company’s specialized workforce development program, which is based on individualized training.

Read MoreThe Why & How of Developing a Talent Strategy

Chief Workforce Development Officer of the Society of Manufacturing Engineers and owner of Human Asset Management talk about workforce readiness, the state of the manufacturing workforce and steps for building a talent strategy.

Read MoreUnique Mold Design Apprenticeship Using Untapped Resources

To help fill his mold design skills gap, Jeff Mertz of Anova Innovations, is focused on high schools and underprivileged school districts, a school that has lower graduation and college entrance rates. The goal is a student-run enterprise.

Read More