The moldmaking and plastics industry faces an unprecedented labor crunch exacerbated by a fragile international supply chain and rapidly growing domestic demand. With reshoring on the rise, the issue of tooling lead times and costs has reached a critical point. Robotics, simulation software and metal 3D printing can significantly reduce the labor required during the moldmaking process, enabling shorter lead times and lower costs. Shops embracing these technologies are solving labor shortages and ensuring longevity as labor scarcity continues.

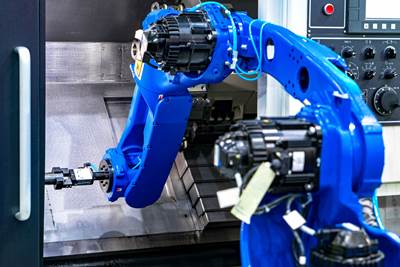

Westminster Tool, a precision toolmaker located in Plainfield, Connecticut, palletized its sinker EDM electrodes and integrated robotics to swap the electrodes during burning, allowing the EDM cell to run lights out with minimal user interaction. Photo Credit: Westminster Tool

1. Robotics

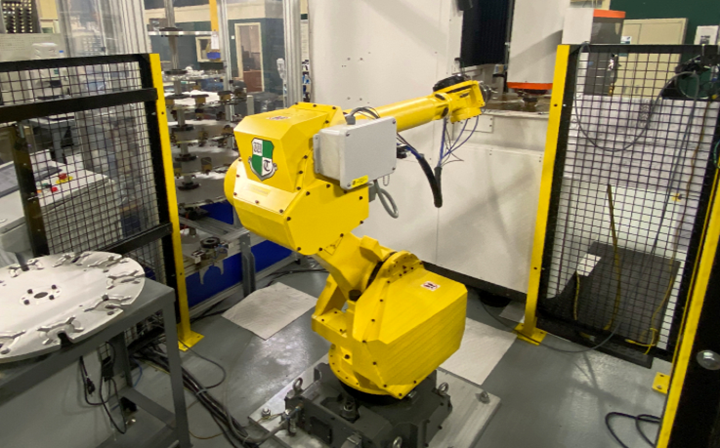

Shops can use robots to automate parts of the toolmaking process, for example, an EDM cell that automatically swaps sinker EDM electrodes, allowing the machine to run lights out without needing a user to change the electrodes manually. A shop can also palletize workpieces, automatically enabling robotics to move pieces from machine to machine. These systems help to eliminate the impact of part setup time and reduce your non-value-added costs by providing a constant flow of parts to the machines, keeping them running. Palletization also improves tolerances and part consistency since tools aren’t being refixtured when moved between machines. While setup can be expensive and requires highly skilled labor, palletization combined with robotics can dramatically increase shop and machine efficiency.

Robotics, simulation software and metal 3D printing can significantly reduce the labor required during the moldmaking process, enabling shorter lead times and lower costs.

2. Simulation

To ensure you optimize the labor you do have, simulation products help understand how molds move through your shop, enabling the identification of backups before they happen. For example, discrete event simulation software that models and simulates a digital twin of your shop floor — including robots, automation, material handling systems and people — to improve shopfloor performance. Once the digital twin is created, experiments can be run to determine the results of different equipment and labor distributions.

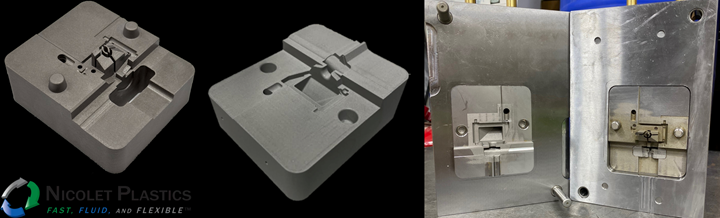

Nicolet Plastics used Mantle’s metal 3D printing technology to print three complex inserts, requiring only a few hours of user interaction. Nicolet could remove all sinker EDM work required, decreasing lead time from 6 weeks to 2 weeks. Plus, the printed insert only needed 10 hours of hands-on moldmaking time. Photo Credit: Nicolet Plastics

3. Metal 3D Printing

Metal 3D printing can automate up to 95% of a mold build with minimal user interaction. For example, printing H13 tool inserts that are close to final after printing. Depending on the surface finish and tolerance required, printed inserts only require grinding to fit into the mold base and finish the ejector pin holes. This small amount of finishing is enabled via technology that prints parts with a D2 surface finish comparable to sinker EDMs and tolerances of ±0.001 inch per inch. Since the printer requires no user interaction during printing and only an hour to set up, it reduces the amount of labor required to build a tool, enabling moldmakers to focus on other critical tasks and increase shop throughput.

Related Content

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreOEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreHow to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

Read MoreLeading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreRead Next

MMT Chats: Pushing Further 3D Printing Development for Tooling

Partnership yields improvements to how tooling components are made with a new level of precision, accuracy and surface finish right out of the printer. Hillary Thomas, Westminster Tool and Paul DiLaura, Mantle tackle these topics with MMT Editorial Director Christina Fuges. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read More3 Ways a Small Mold Builder Uses 3D Printing

Mold builder uses 3D printing for simultaneous mold manufacturing, conformal cooling and hybrid designs.

Read MoreHow to Start Automating Your Moldmaking Operation

A few fundamentals of moldmaking automation include identifying key areas and places to avoid and addressing common concerns and roadblocks.

Read More