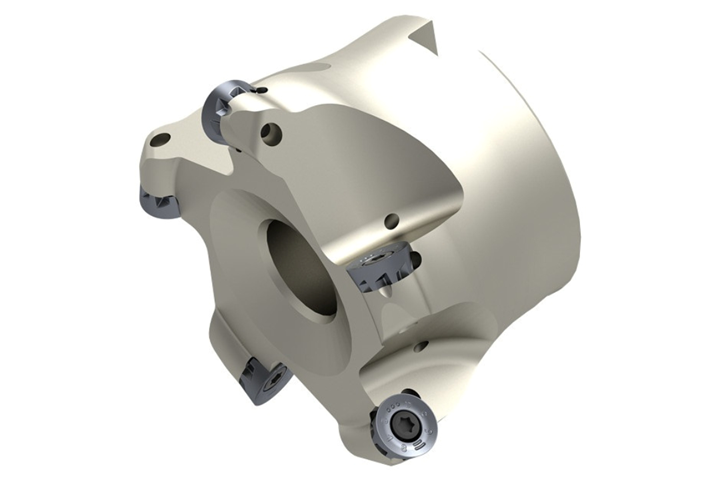

Shell Mill Supports Variety of Rough Milling Strategies

The Ceratizit MaxiMill 251 is optimal for pocketing, mold and die roughing, face milling, slotting and helical interpolation of holes.

The MaxiMill 251, presented by Ceratizit is a shell mill, also known as a button cutter, that offers various rough milling strategies. Utilizing a stable round insert, the positive mounting position provides a soft cutting action, giving lower cutting forces for a smooth cut.

MaxiMill 251 features six face-mounted inserts, with a 2" cutting diameter (max is 2.5") and a 0.24" maximum depth of cut. Applied in a variety of applications, the MaxiMill 251 can be used for pocketing, mold and die roughing, face milling, slotting and helical interpolation of holes. It is also commonly used in aerospace and energy sectors, as it works well in high-temperature alloys, steel and stainless steel. In addition, the MaxiMill 251 is an optimal cutting solution for unstable pieces, older and lighter machines that cannot achieve the performance needed of high-feed cutters, as well as multi-axis machining.

Related Content

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

.png;maxWidth=300;quality=90)