February 2024 Issue

February 2024

Digital Edition

Features

Featured articles from the February 2024 issue of MoldMaking Technology

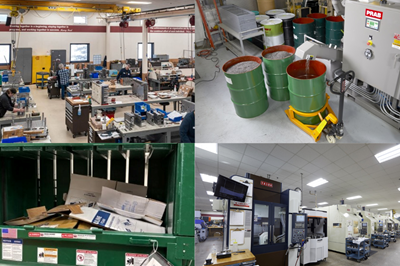

Embracing ESG: One Mold Builder's Path to Sustainability and Success

The story of how a company in the moldmaking, injection molding and metal parts industry is navigating the challenges and opportunities associated with sustainability.

Read More

Extensive Evaluations Build The Plastek Group’s EDM Arsenal

Sinker and wire EDMs selected for speed, volumetric accuracy, surface finish, reliability, cost of ownership and extensive warranty.

Read More

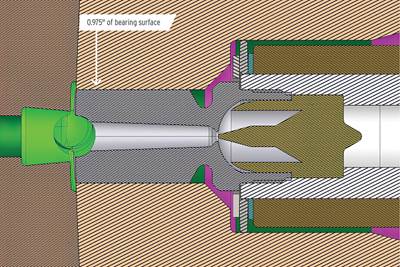

Hot Runner Truths, Myths and Overlooked Areas

Addressing hot runner benefits, improvements and everyday issues from the perspective of decades of experience with probably every brand on the market.

Read More

How to Build the Right Automation System

Seven considerations when developing an automation solution for your customers.

Read More

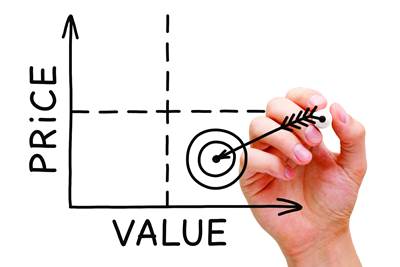

Steps for Determining Better Mold Prices

Improving your mold pricing requires a deeper understanding of your business.

Read More

Editorial Advisory Board 2023-2026: Corey Alton Fox, Accede Mold & Tool

The 2023-2026 version of MoldMaking Technology’s EAB features a new crew of industry professionals. Meet Corey.

Read More

Perspectives on Sustainability in Mold Building: A Diverse Outlook

In conversations with individuals involved in the mold building industry, a variety of perspectives on sustainability emerged, showcasing the multifaceted nature of the term.

Read More

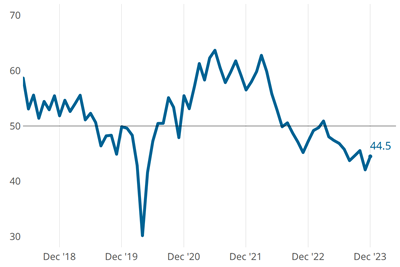

Contraction in Moldmaking Activity Slowed According to GBI

The moldmaking index almost bounced back to November’s reading but stopped one point shy, as most components slowed or stabilized contraction in December.

Read More

Balancing People, Process and Technology for Program Management Success

Using the expertise of its team members and emphasizing efficiency, this Michigan mold builder's process is designed to function as a highly efficient system.

Read More

How to Machine Aluminum Molds to Enhance Efficiency and Quality

Ways to optimize the machining process to fully leverage the benefits of an aluminum mold.

Read More

.jpg;maxWidth=300;quality=90)