Versatile End Mills Key for Moldmaking Operations

Said to be impossible to clog, the new series of Pow-R-Feed M936 cutting tools from IMCO Carbide Tool delivers free cutting at fast part cycles and high speeds and extended tool life in die steels.

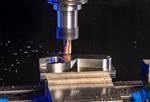

IMCO Pow-R-Feed M936 end mills are designed specifically for aggressive roughing and pocketing in steels and titanium with much faster material removal. IMCO’s proprietary end design enables aggressive helical entry parameters — no predrilled starter hole needed, saving time and a tool change. The aggressive geometry of the flutes and end face also are said to make the tool virtually impossible to clog. Photo Credit: IMCO Carbide Tools

IMCO Carbide Tool Inc. has developed a new series of Pow-R- Feed M936 end mills with the versatility to machine a slot for wire channels, cut a helical entry into an insert pocket, rough the pocket with a traditional or HEM tool path and face off the rough block to square it up, all without a single tool change.

Designed for faster part cycles and high speeds, regardless of a machining station’s horsepower, the M936 designs feature wiper flats and flute geometry ideal for producing good surface finishes on workpiece sidewalls and floors. Open-ended face geometry enables their use for downward cuts. The series is also ideal for machining 3D impression shapes.

One of the most distinctive features of the M936 six-flute is its extended tool life in die steels, thanks to the variable helix and variable index effects on vibration damping, a specially engineered carbide core and an AlTiSN slippery-smooth coating, which also prevents chip buildup and enables high feed and metal removal rates. Free cutting action for the M936 end mills means reduced heat transfer to the workpiece and less risk of warpage.

“This is the cutter for any programmer machining steels, stainless steels and titanium on three-axis to five-axis CNC machining centers who wants to run fast and helical enter, ramp, slot and peripheral mill at optimal feed rates,” Matt Osburn, vice president, technical director for IMCO, adds.

Related Content

-

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

.png;maxWidth=300;quality=90)