Face Milling Inserts Dedicated to Workpiece Material Range

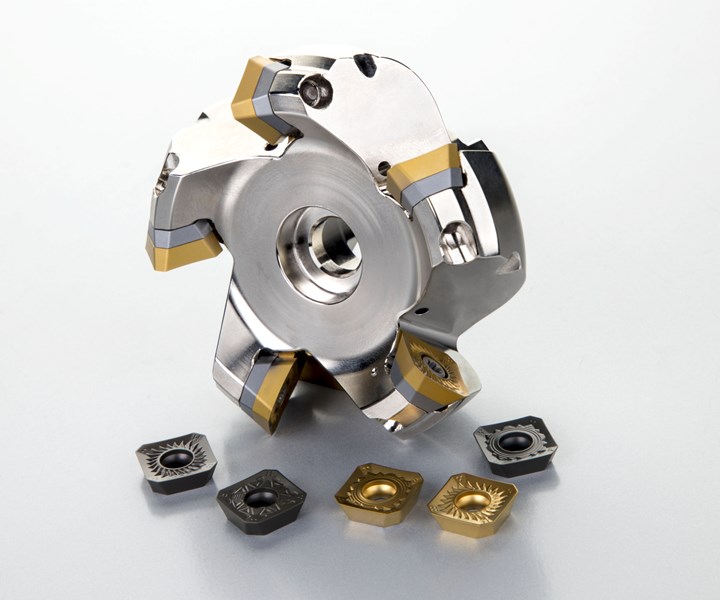

Dormer Pramet launches five variants of its square-shaped positive inserts, each of which are designed for roughing or milling a specific metal material group.

Dormer Pramet, working with a variety of segments including mold and die manufacturers, offers customers a new assortment of versatile face milling inserts. Five variants of square-shaped positive inserts have been added for depths of cut up to 6.4 mm. The range is suitable for a variety of general engineering and maintenance and repair operations (MRO) machining, with several application-specific geometries and grades available for machining any workpiece material.

The Pramet SDMT 13 pressed inserts are designed with economy in mind. Its M geometry enables light and medium cuts, while R geometry is focused more on roughing. Both geometries are versatile for milling steels, cast irons and hard steels.

The Pramet SDET 13 precision ground inserts are dedicated for use in specific workpiece material groups. Sharp F geometry is the ideal choice for secure machining of stainless steels and heat-resistant super alloys. A polished, extra sharp FA geometry is said to allow for productive machining of non-ferrous materials. An additional wiper insert XDET 13 is also available to provide high surface quality in larger diameter cutters and high feed rates.

A wide assortment of cutters is available to support the new range of inserts. The (I)SSD13F comes in Weldon and Shell styles, with a wide range of sizes 32-250 mm (1.25-10").

A carbide shim on the insert seating gives extra stability and process security, while protecting the cutter body for high durability. These cutters also utilize internal coolant delivery for improved chip evacuation to achieve high surface quality.

Related Content

-

The Secrets to Hard Milling Success

The Secrets to Hard Milling Success

-

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

.png;maxWidth=300;quality=90)