Mold and Die End Mills Target Hard Machining

More than 20 new options in Emuge-Franken’s hard-cut ball nose and torus end mills line offer up to 60% longer tool life and excellent surface finish when roughing, pre-finishing, finishing and high-speed cutting.

Share

Read Next

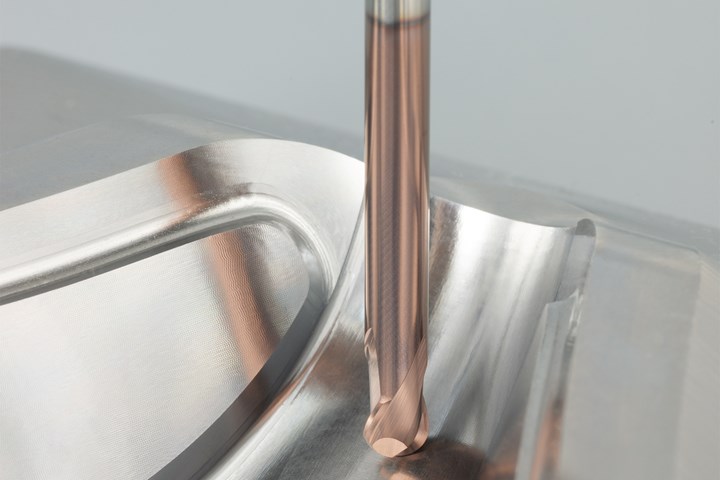

Emuge-Franken’s line of hard-cut ball nose and torus end mills line offer significantly longer tool life, and optimal surface finishes in hard materials.

More than 20 new solid carbide end mills in the hard-cut ball nose and torus line provide high-performance milling in materials hardened up to 66-70 HRC, as well as in unhardened steel and cast materials. Due to optimized tool geometry and high-performance solid carbide construction, the end mills offer up to 60% longer tool life and produce the highest quality surface finishes, according to the company.

Specifically optimized for hard machining including roughing, pre-finishing, finishing and high-speed cutting applications, Emuge-Franken’s end mills feature new precision cutting edge geometry and concentricity, and have a tighter h4 shank tolerance. The ball nose end mill has a diameter tolerance of -0.014 mm and a radius tolerance of -0.007 mm, and the torus end mill has a diameter tolerance of -0.015 mm with a radius tolerance of ±0.005 mm. A TiAlN tool coating, which indicated high performance in internal and customer testing, significantly extends tool life.

Related Content

-

Machine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.