Tips

Five Ways to Tackle Tough Mold Design Tasks with Digitalization

Transform static 3D designs into animated 4D designs that simulate motion and interaction of complete mold systems to improve design workflow.

Read MoreHow to Use Flushing to Clean Cooling Passages and Heat Exchangers

Six key questions to ask before investing in a flushing system.

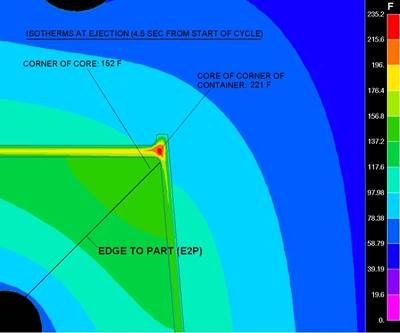

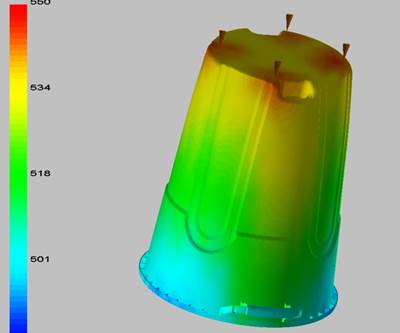

Read MoreUnderstanding the Value of Scientific Injection Mold Cooling

Injection molds are heat exchangers, so proper cooling is necessary to improve part quality, maximize profits and maintain your company’s reputation.

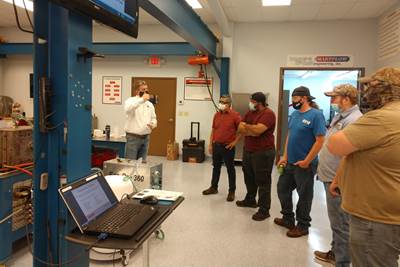

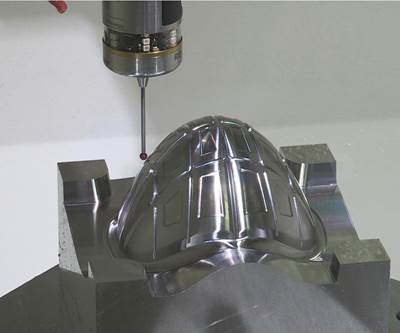

Read More3 Lessons Learned about On-Machine Inspection

A prototyping specialist shares its success with on-machine inspection that it believes can apply to many shops.

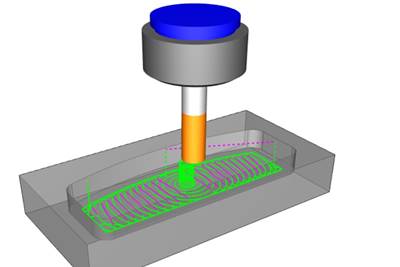

Read More5 Ways to Cut Programming Time

Steps mold builders can take to reduce programming times and improve machining processes.

Read MoreHow to Improve 3D-Printed Conformal-Cooled Mold Insert Performance

Coated conformal cooling channels can prevent scaling and corrosion in injection molds, increasing heat transfer, improving performance, and reducing outages.

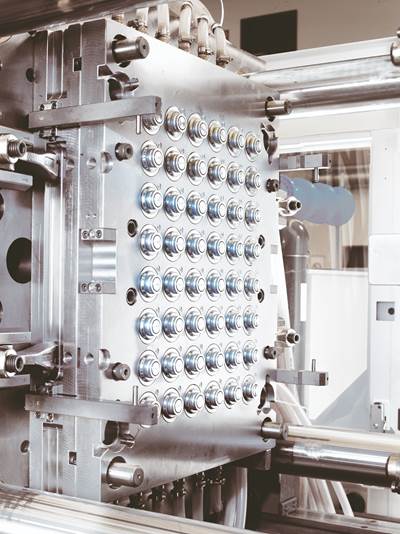

Read MoreHow to Design High-Efficiency Capabilities into an Injection Mold/Molding System

Mold builders can boost profits and part quality with expert analysis and optimization techniques.

Read MoreSteel Choice Matters for Corrosion Resistance

A free-machining stainless steel faces the extremely corrosive injection molding environment head on, improving machinability and stability.

Read MoreHow to Ensure Quality Offshore Tooling

When working with a foreign mold builder provide clear expectations and conduct comprehensive reviews throughout the moldmaking process to ensure a robust mold.

Read MoreHow to Improve Tooling Supply Chain Transparency

An automated tooling supply chain management system will maximize efficiency, minimize risk and improve tooling supply chain transparency.

Read More