Tips

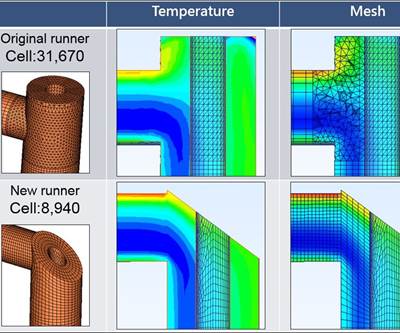

Realizing Complicated Runner Designs Using Generation Mesh

High-speed, high-quality mesh technology automatically generates the high-resolution hexa-based mesh in which the mesh model perfectly matches the original runner design with high accuracy.

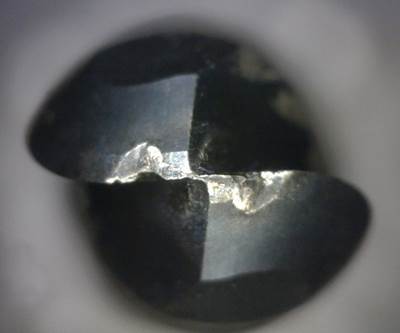

Read MoreAdvancing Anode Assembly Fabrication

A look at the science of conforming anode assembly for chrome plating.

Read MoreThe Value of the Right Cutter Carbide Material and Coating

Consider mirror-edge geometry and carbide-grade combination heat-resistant PVD coatings when trying to solve mold machining challenges.

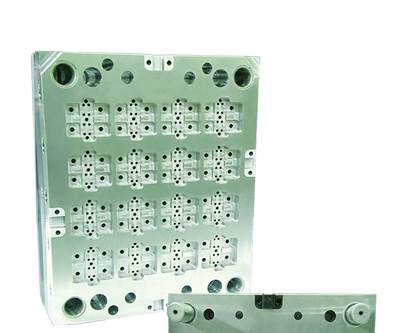

Read MoreSix Considerations for Evaluating a Hot Runner System

Details matter when it comes to selecting and integrating a hot runner system. This guide makes that process easier by covering those details thoroughly.

Read MoreWelding Pre-hardened 40 Rockwell Material

Key tips help ensure safe shop welding practices when using pre-hardened 40 Rockwell material.

Read MoreSteps for Properly Evaluating a Mold Release Product

Here are some essential steps to follow when selecting the right agent to help eliminate issues that slow down cycle time.

WatchIntelligent Monitoring with MTConnect

A major challenge to the wide adoption of the MTConnect standard on the shop floor is a lack of understanding about what is required to implement the standard. The most common issues are a mismatch between the adapter and the machine, a missing agent, a wrong error log setting, firewall interference, duplicate port configuration, inconsistent file names and incorrect adapter IP addresses.

Read MoreStreamlining Roll Dimension Calculations for Mold Components

A new roll dimension calculator streamlines the use of roll pins to measure core pins, wedge blocks, shut-off surfaces or electrode details to determine the exact size of a workpiece’s angled detail.

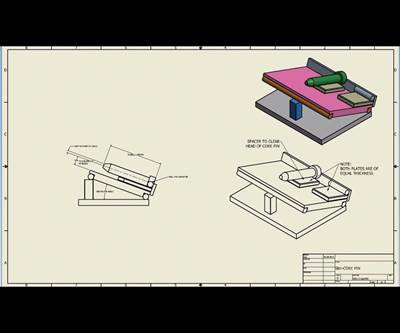

Read MoreHow to Advance Molding Undercuts with Collapsible Core Design

A new flush-style collapsible core design might help to overcome objections to using the technology and advance the molding of undercuts.

Read MoreChoosing Between Solid Carbide and Indexable Cutting Tools

Criteria like machine tool spindle power, workpiece geometry and material, CAD/CAM for CNC programming and fixturing drive rough milling cutter selection.

Read More

.jpg;maxWidth=300;quality=90)