Tips

Tips for Mitigating Chatter and Vibration

A review of the problems of machine vibration and the strategies and tooling systems that that can stop them.

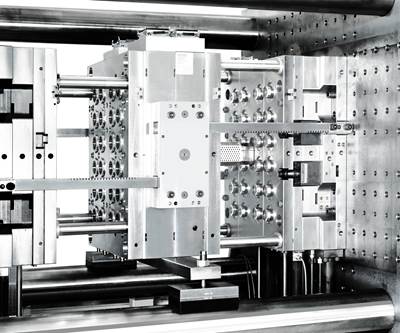

Read MoreHow to Design and Analyze the Right Clamping System

The use of innovative clamping systems to optimize the moldmaking production process requires consideration of five factors based on Industry 4.0 principles.

Read MoreHow to Maintain and/or Upgrade a Robot

Create a strategic plan to manage the lifecycle of a robot.

Read MoreConsiderations for AM Powder for Tooling

The start of any good product is the raw material, and that includes additive manufacturing powder for tooling.

Read MoreHow to Better Balance Family Molds

A servo-driven valve gate can provide superior processing for family molds with significant variances in part sizes and volumes.

Read MoreWhen Is 3D Printing Cost Effective?

Hype continues to surround additive manufacturing. These three factors can help determine whether a part is worth 3D printing.

Read MoreHow to Improve Melt Distribution with Diffusion-Bonded Manifolds

Diffusion bonding for manifold manufacturing offers design freedom for optimizing hot runner melt distribution, reducing color change-over time, cavity-to-cavity weight variation, peak injection pressures, melt degradation, and resin flow stress.

Read MoreHow to Avoid Tool Steel Corrosion

A mold builder should consider corrosion resistance, hardness, machinability, processing, polishability, operational environment and wear resistance during tool steel selection.

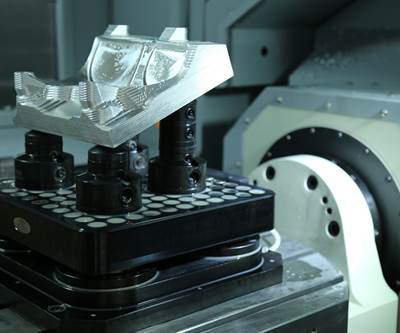

Read MoreHow to Hard-Mill Effectively

These are five rules for improving cutter performance and cutter life while maintaining tight tolerances during hard milling.

Read MoreReducing Risk to Implement CAM Software Successfully

Following a training and implementation period, new software technology can provide a strong return to the business and be key to long-term success.

Read More