Tips

Improve Your Current Efficiency Rate

Ernie Green Industries gives an account on how it took on more EDM-intensive work without investing in machines or staff.

Read MoreCorrect Selection, Consistency and Coatings

As plastic part geometry requirements grow in complexity, appropriate equipment selection and advancements and keeping up with technology track records are recommended.

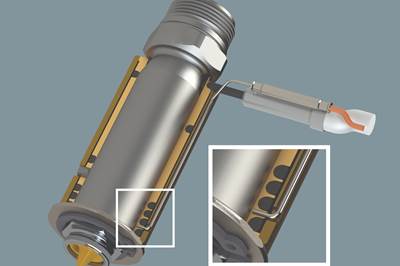

Read MoreTroubleshooting "Actual" Hot Runner Controller Temperature

The root cause of a recent part defect was suggested to be the delivery of a melt that was too hot. The true root cause, however, was something else entirely.

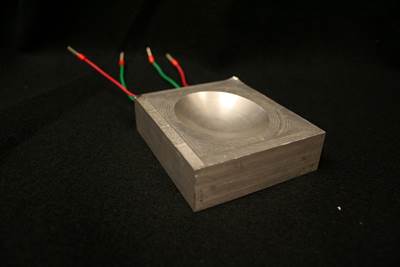

Read MoreHow to Apply Ultrasonic AM to Moldmaking

An ultrasonic welding system brings a unique hybrid additive and subtractive process to moldmaking.

Read MoreEngineering-Centric ERP Helps Mold Builders Keep Up with Constant Changes

Mold builders operating on thin margins must create a competitive edge, reduce costs, and improve profit margins. In the engineer-to-order (ETO) environment, reducing duplications and eliminating errors can only happen by gaining control over manufacturing processes.

Read MoreHow Latch Locks Speed Mold Build Time

Ten key features and functions of internal and side-mounting latch-lock devices that help moldmakers build molds faster and more safely.

Read MoreFrom CAM, Cutters and Cooling to Corrosion, Cleaning and Control

A review of the year’s top tips on technologies and strategies to improve moldmaking operations from design to first shot.

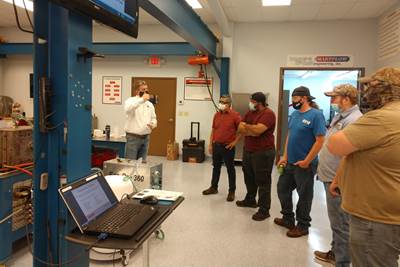

Read MoreFour Benefits of Improved Employee Training for MoldMakers and Molders

Industry “know-how” and attention to everyone’s development can mean big profits for your business.

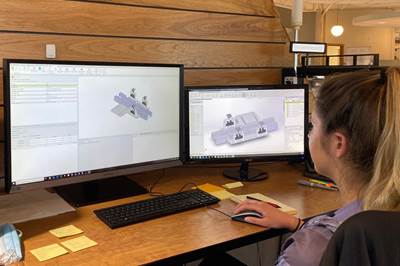

Read MoreFive Ways to Tackle Tough Mold Design Tasks with Digitalization

Transform static 3D designs into animated 4D designs that simulate motion and interaction of complete mold systems to improve design workflow.

Read MoreHow to Use Flushing to Clean Cooling Passages and Heat Exchangers

Six key questions to ask before investing in a flushing system.

Read More

.jpg;maxWidth=300;quality=90)