Tips

Understanding Diamond Compounds

Diamond compounds, with their varied grades, colors and base options, provide a comprehensive solution for mold builders in need of precise and superior polishing across diverse materials and applications.

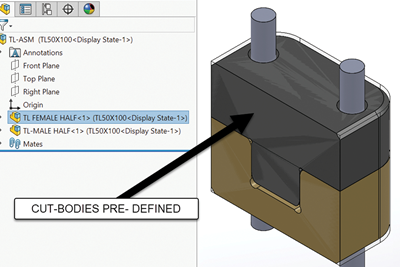

Read MoreHow a Small Programming Change Cuts Cycle Time in Half

Overriding the CAM system when milling a series of lifter pockets helps to improve metal removal rate and increase feed rates.

Read MoreHow to Enhance Efficiency, Reliability of Mold Components With Metal Bonding/Sintering Technology

A look at the metal bonding capabilities, application procedures, material compatibility and quality assurance measures of metal bonding/sintering.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Build the Right Automation System

Seven considerations when developing an automation solution for your customers.

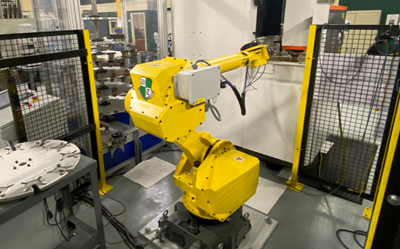

Read More3 Technologies to Help Fill the Skills Gap

Moldmakers can address the labor challenge with robotic systems, simulation products and metal 3D printers.

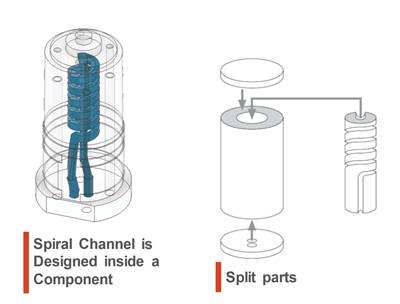

Read MoreHow is an Aluminum Mold Energy-Efficient?

Nine ways aluminum molds save energy and production costs.

Read More5 Steps to Get Started With Digitalization

Knowledge, a strong partner, an internal champion and an active regular participation in highly visible data will help smaller mold shops with digitalization.

Read MoreA Simple Guide to Spindle Repair

Understand the causes of spindle failure and the steps for proper repair.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)