Tips

How to Address the Mold Engineering Skills Gap

Four ways to equip mold engineers with the necessary knowledge to tackle the skilled workforce crisis.

Read MoreCNC or 3D Printing: 5 Factors to Consider

Accuracy, time, cost, nimbleness and application considerations help to determine if a shop should use CNC machining or 3D printing.

Read More5 Sinker EDM Advancements

Speed, machine design, software, artificial intelligence and automation help maximize sinker EDM productivity.

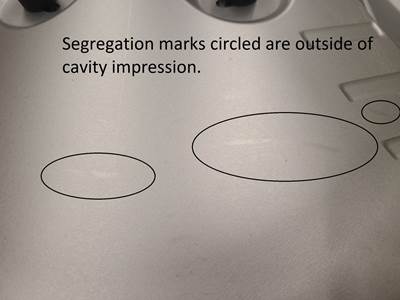

Read MoreHow to Produce More Accurate Molds and Reduce Rework

Patented micro-milling process for manufacturing steel plate flat and parallel helps mold builders shorten mold build times and increase accuracy.

Read MoreThe ROI of ERP

Seven reasons why a mold builder needs to invest in enterprise resource planning software and technology.

Read MoreThree Ways to Accurately Machine Hardened Mold Materials

Three cutting tool design considerations to improve process reliability and cost efficiency when deep-hole drilling molds.

Read MoreHow to Eliminate Streaks and Weld Problems with Laser Technology

Laser technology overcomes streaking and welding challenges for new mold textures and texture repair.

Read MoreFive Ways a Hot Runner Is Key to Processing Reinforced Materials

A trusted hot runner supplier should work closely with mold builders and molders to manage the expectations (and realities) of supporting the specification, tool design, installation and service of a hot runner system.

Read MoreFour Uses for Tactile Probing and Laser Scanning in Moldmaking

Laser trackers with their probing and scanning capabilities are embedded in almost every stage of the moldmaking process.

Read MoreTwo Reasons to Form Additive Tooling Partnerships

Partnering with experienced 3D printing resources is essential to remaining competitive in today’s ever-evolving moldmaking industry.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)