Tips

Ten Things Mold Builders Should NOT Do

What you don’t do can be just as important as what you do, sometimes even more so. One thing great mold builders do is take note of what gets in the way of their success and stop doing it.

Read MoreHow To Get Buy-In from Your Team for ISO 9001

Here are four tips for getting your team on board once you’ve decided to become ISO 9001 certified.

Read MoreHow to Protect Soft Base Materials

Choose a suitable mold coating to take the abuse and save your base material.

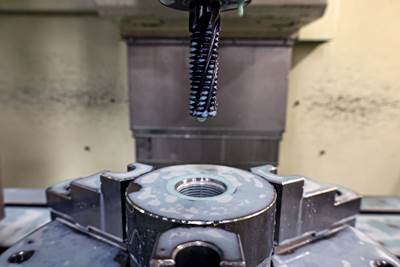

Read MoreWhen to Use Solid Carbide Thread Mills or Indexable Thread Mills

Pointers for choosing solid carbide thread mills versus indexable thread mills.

Read MoreCutter Considerations for Hybrid Additive Manufacturing

Four tips for applying the right cutting tools in hybrid additive manufacturing.

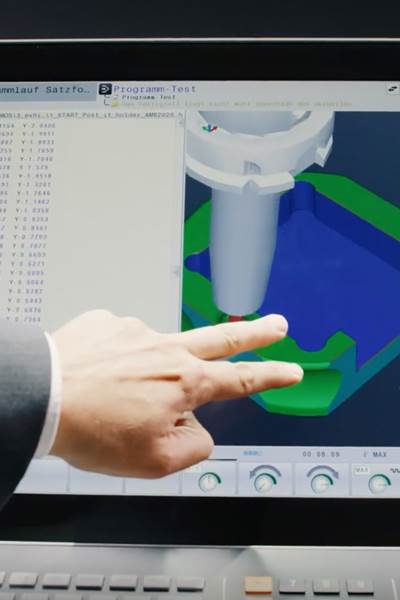

Read MoreSix CNC Control Features for Moldmakers

A CNC control should have features to automatically smooth the axis movements or allow the operator to set tolerance limits manually.

WatchFive Things a Mold Builder Should Know about Non-Contact Blue Light 3D Scanning

Mold builders who use non-contact blue light 3D scanning reap the benefits of digitization throughout the mold manufacturing process.

Read MoreHow to Use Hybrid Additive Manufacturing

A look at directed energy deposition (DED) and powder bed fusion (PBF) additive technologies for moldmaking applications.

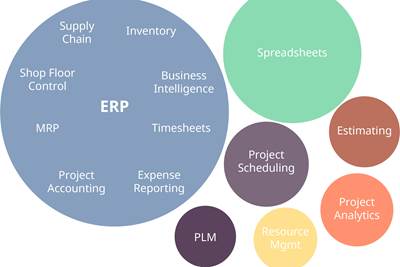

WatchHow to Focus Better on the Business Side of Projects with Nontraditional ERP

The right ERP solution can help a mold manufacturer run the facility like a project-based business to increase productivity and profitability.

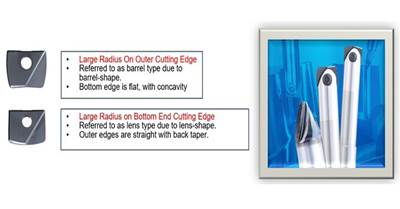

Read MoreWhy Mold Builders Should Consider Barrel Cutters and Lens Tools If They Haven’t Before

Reduce machining cycle times and improve surface finishes of cavity and core work with barrel cutters and lens tools.

Read More

.jpg;maxWidth=300;quality=90)