Steel Choice Matters for Corrosion Resistance

A free-machining stainless steel faces the extremely corrosive injection molding environment head on, improving machinability and stability.

Tool steel resists condensation, and waterline corrosion, which is especially important as the use of corrosive materials like fire-retardant additives, PVC and aminoplast increases. However, with every positive there is typically a negative. For example, corrosion-resistant plastic injection mold steels require additional machining time that increases wear, and more complex mold bases cause 60 percent of the steel to become chips.

To address these challenges, steel suppliers continue to develop specialty steels to combat the extremely corrosive injection molding environment while improving steel’s machinability and stability. For example, a free-machining stainless steel that offers a balance between machinability and corrosion resistance by combining a special chemical composition with a special heat-treatment process.

Low-carbon content and alloying elements such as chromium, manganese, and other additions play an important role in this free-machining stainless steel. The alloying elements are added during production and combine to yield optimal hardness, machinability and corrosion resistance (see Table 1).

| C | Si | Mn | S | Cr | Additions |

|---|---|---|---|---|---|

| 0.05 | 0.40 | 1.30 | 0.15 | 12.50 | + |

Table 1. Chemical composition in weight-%.

The heat treatment process further refines the steel at the final production process. The material is heated to a temperature of 1,475°F under controlled conditions and quenched in water or a polymer, which promotes the characteristic of a homogenous microstructure yielding material that is consistent throughout and extremely stable.

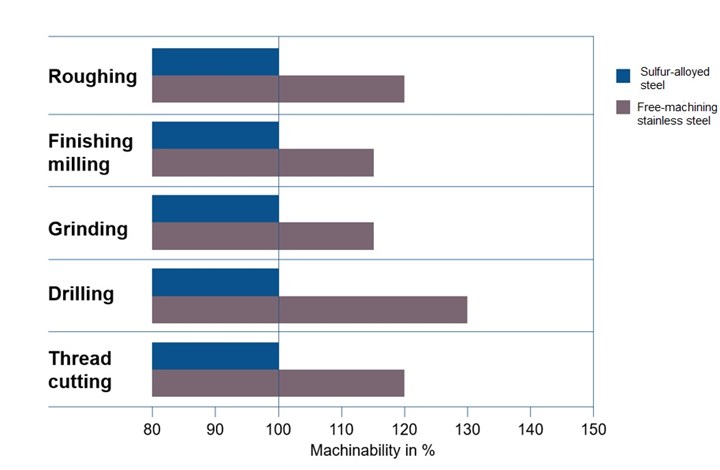

To assess corrosion resistance and determine the appropriate testing method, the mold builder must understand the type of corrosion that may occur. The corrosion behavior is a system property. The corresponding tests only reveal the classification of the steels in the same testing structure. Several tests were conducted on this free-machining stainless steel in laboratory conditions with media containing chloride, condensation and in slightly acidic conditions. A sulfur-alloyed steel was tested for comparison. The results indicated that the free-machining steel and the sulfur-alloyed steel are nearly identical in corrosion resistance. The free-machining steel also offers an increase in cost-effectiveness and productivity by decreasing machining cost and lead times (see Figure 1).

Figure 1. Comparing machinability in % (sulfur-alloyed steel 325 HB, free-machining stainless steel 370 HB).

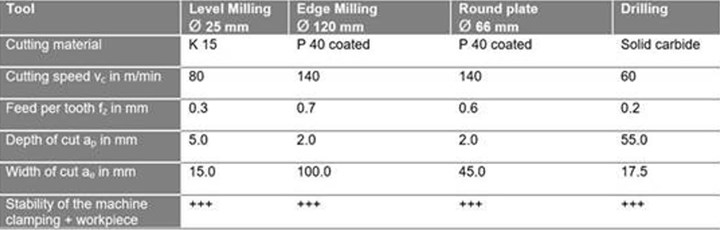

To optimize machining efficiencies and lead times, refer to the process recommendations in Table 2.

Table 2. Machining values for free-machining stainless steel (hardness 290 - 332 HB)

Mold material choice is one of the key variables influencing plastic part production profitability, so it may be time to consider the machinability, dimensional stability and weldability benefits of a free-machining stainless steel, which can also enhance mold performance with its toughness, minimal residual stresses, and good corrosion resistance.

Related Content

Coating Technology Enables Tough Mold and Die Steel Machining

Millstar, a part of Cole Tooling Systems, presents a multi-layer hybrid nanocoating for cutting tools that provide key benefits for increased efficiency in any machining operation.

Read MoreVIDEO: AM Powder Addresses Current Inefficiencies, Sustainability and Skills Gap

Steel supplier discusses high thermal conductivity metal powders that also address the skills gaps via user-friendly materials and promote sustainability via durability and higher cycle counts.

Read MoreProject Reveals Added Benefits of New P20 Grade Steel in Machinability, Cycle Time and No Stress Relief

MoldMaking Technology's Christina Fuges talks with General Motors' Shane Appel about a project testing a new P20 steel grade's dimensional stability.

Read MoreMicro-Milled Steel Plate Cuts Mold Build Times by 10-15%

Steel 21 emphasizes its tighter tolerances, improved surface quality and speed of processing using the patented “21 Micro Milling” process.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More