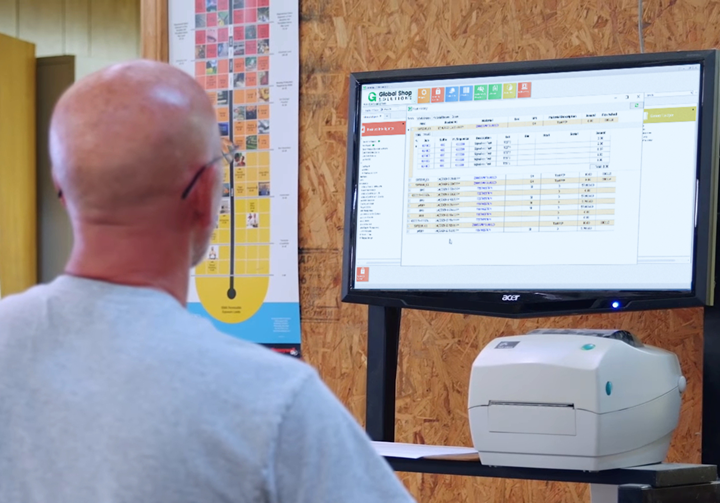

Efficient, accurate scheduling helps mold builders deliver on time, manage change and meet customer expectations. Photo Credit: Global Shop Solutions

Enterprise resource planning (ERP) software can pay for itself within the first year and generate hundreds of thousands of dollars in cost savings each year after. Here are seven reasons mold builders should use ERP software, along with a handful of tangible benefits for businesses following an ERP software implementation.

1. Move Parts Through the Shop Faster

When you get parts through the shop faster, customers will order more. In addition, some customers report that machinists no longer waste time hunting down routers, drawings, BOMs, POs or inventory lists. This adds up to a 100% increase in logistics efficiency.

When you move molds through the shop faster, efficient and accurate schedules are based on true capacity, quality issues are corrected in real time instead of afterward, workers always know what to work on at present and in the future and you instantly know the status of all jobs in real time.

2. Schedule and Deliver On Time

Efficient, accurate scheduling lets you deliver on time, manage change and uphold promises to your customers. Some customers mentioned on-time delivery rates nearly doubling, from an average of 50% to a consistent 99%. They attribute the remarkable increase to two key factors: (1) improvement in scheduling and production processes and (2) data visibility throughout the ERP system.

When you schedule and deliver on time, you can correctly estimate lead times, identify production bottlenecks, know the status of all jobs, know your true capacity for machines, work centers and personnel and see how inserting a job into the schedule will affect other jobs, all in real time.

ERP software provides a hidden return: sales growth from delivering a quality mold on time every time and knowing your bids are competitive, profitable and margin-true.

3. Achieve a 99% Quality Rating

Consistent, near-perfect quality makes it easier to win more jobs. For example, some customers shared that they achieved a quality rating of 99.67%. When you achieve a near-perfect quality rating, your shop floor can always work off the correct document versions and identify bad parts as they are made (rather than during or after shipping).

Workers can also view everything in a single dashboard, take and document cause and corrective actions in real time, trace every part with 100% accuracy as it moves through the shop floor and quickly produce quality documentation for ISO and other compliance auditors.

4. Grow Sales

ERP software provides a hidden return: sales growth from delivering a quality mold on time every time and knowing your bids are competitive, profitable and margin-true. Some customers describe that since implementing ERP software, sales have grown by 600%, with only a 300% increase in their workforce.

You can grow sales faster when sales orders are accepted and work orders are sent to the shop floor within minutes. Also, sales will increase when you can answer any customer question in a single phone call from a single screen, know job costs and margins, enable precise estimating and quoting, access entire sales history instantly by a customer or part number, and take on more work without increasing administrative overhead.

5. Know Job Costs

When you can trust your costing process, you know how much each job costs. Fast quoting and accurate pricing brings in new customers and backs existing ones. Some customers passed on that they couldn’t absorb labor, manufacturing and overhead costs before using ERP software and technology — they were all just part of the total expenses. Now they have actual costs for every job, enabling them to make informed decisions about their production and installation processes.

When you know your job costs, you can track direct labor down to the penny for each job and job sequence, track material costs in real time as jobs move through production, compare actual versus estimated costs while the job is in progress, know precisely what you have in inventory and what it cost and know margins are correct.

When you can trust your costing process, you know how much each job costs.

6. Maintain Accurate Inventory

Knowing jobs are never late from lack of materials or are more expensive than they should be reduces risk. In addition, some customers disclosed that they know in real time the exact location of all their inventory in any location or across multiple facilities and what’s in transit between them.

When you can maintain precise inventory, you can perform lot bin tracking resulting in complete traceability of parts; physical inventory counts are fast and accurate, barcoding all material lets you know exactly what you have in inventory and where it is, you rarely pay expedited shipping charges for incoming material and jobs are never late due to lack of raw materials.

7. Control Labor Costs

When you can control labor costs, you can track labor down to the minute for jobs and job sequences, improving your ability to respond to customers, reduce indirect costs by holding operators accountable for their time, track the number of hours in each job in real time, cut administrative overhead costs by simplifying and automating back-office processes and minimize overtime by reducing rework, overdue jobs and time spent waiting for parts.

With software and technology, mold builders can log on and off jobs and job sequences without leaving their workstations. Collecting time and performance metrics becomes fast, efficient and accurate, reducing and controlling labor costs. Some customers revealed that they have increased revenue since implementing ERP software and technology and have only added minimal staff to the operation. That’s the biggest and best statistic of all.

Related Content

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreTolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.

Read MoreFour Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

Read MoreRead Next

How to Optimize Your ERP Implementation

Proven methodology for using enterprise resource planning.

Read More5 Reasons to Consider Automation

As ongoing advances enable machines and humans to get better at talking to each other, eventually more shops will become more automated. If your shop hasn’t yet looked into upping its automation game, here are five reasons why you should.

Read MoreTen Things Mold Builders Should NOT Do

What you don’t do can be just as important as what you do, sometimes even more so. One thing great mold builders do is take note of what gets in the way of their success and stop doing it.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)