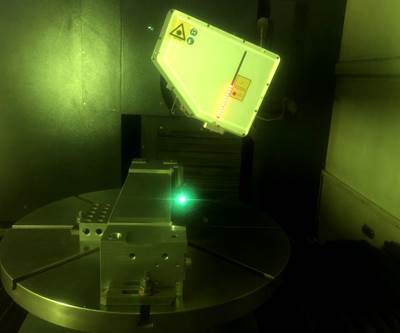

A mold cavity, ready for laser texture application. Photo Credit, all images: Custom Etch Inc.

The increased use of plastic parts has increased the application of textured surfaces to their finish. Textures can be applied for aesthetic and functional purposes.

Pattern designs have progressed from simple, leather-like or random deep surfaces to very shallow stipple or geometric shapes that display intricate, delicate appearances.

Traditionally, shops use acid etching to apply mold textures into steel surfaces, which requires a lot of upfront preparation — disassembling the mold, cleaning the surface and manually protecting areas not to be textured.

First, texture areas are blasted for pattern adhesion, and then a transfer film is manually placed and carefully mated to assure the texture does not show any mismatches. Acid is then applied to chemically etch away the metal and create the desired surface pattern. After exposure, the mold is blasted again to remove any residues and for gloss adjustment. This process can take days for simple patterns or several weeks for more complex and custom patterns. Laser texturing, however, is an alternative option that applies the controlled use of digital lasers to ablate or remove the metal in a designated pattern.

Digital laser technology does not require any preparation. It also offers freedom of design, safety, higher quality, unlimited design options, blended patterns with seamless transitions and features not possible with acid etching. In addition, five-axis CNC lasers apply patterns directly to the surface with no environmental issues for chemical disposal.

Laser texturing, however, is an alternative option that applies the controlled use of digital lasers to ablate or remove the metal in a designated pattern.

Eliminate Streaks

The occasional appearance of streaks in the textured steel surface can arise from acid etching. These single or multiple areas appear as lighter or darker lines in the desired pattern and transfer to the surface of the molded plastic parts.

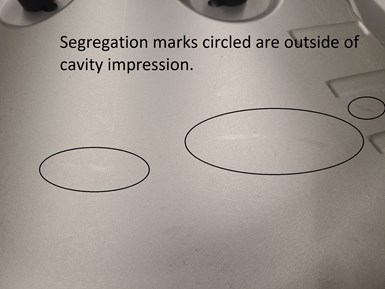

The segregation marks circled are outside of the cavity impression.

Steel suppliers have traced texture streaks to elemental segregation within the steel blocks used for molds. Segregation occurs when certain steel elements separate during initial metal solidification and form areas that react differently when applying a texture with acid etching. Segregation is present to some degree in all steels and is a natural phenomenon that is difficult to measure or predict inside a raw mold block.

Tackle Weld Repair

A textured mold can sometimes require welding for repair or design revisions. The weld deposit is likely slightly different in chemistry or hardness from the original base metal. Using acid to retexture the weld area may not match the original texture. Lasers are unaffected by weld or hardness issues and will produce a result as good as the original.

Laser texture shows no segregation.

High-volume textured molds will show wear that requires a reapplication of the surface pattern. Lasers can fully replicate the pattern,whereas a second acid-etched texture may vary slightly.

This is critical when multiple new molds are required to display identically matched textures, such as family molds for interior automotive parts. Automotive OEMs demand perfect texture matches despite possible differences in the mold materials used.

Related Content

How to Correctly Size a Hydraulic Cylinder

This week Randy shares steps for correctly sizing a hydraulic cylinder on a mold.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreWhat You Should Consider When Purchasing Modified P20 Steel

When buying P20 steels that have been modified, moldmakers must be aware of the variations and key issues that affect delivery, cost and lead times.

Read MoreHow to Determine the Proper Vent Depth

Vent depth is critical to optimizing mold performance, so here is one approach to finding that elusive right number.

Read MoreRead Next

Higher-Level Laser Mold Texturing

Eroded, sandblasted and chemically-etched mold textures are now 100-percent lasered at this Germany-based service provider.

Read MoreThe Advantages of Digital Laser Technology for Mold Texturing

Understanding the nuances and benefits of laser ablation and when to use it.

Read MorePerformance and Price Drive Developments in Mold Materials

Mold material suppliers are working to develop new, improved mold-material grades that will deliver on customers’ need for machinability, toughness, thermal conductivity and price.

Read More

.jpg;maxWidth=150;quality=70)

.jpg;maxWidth=400;quality=70)