Machining

Jig Boring for Mold Base Accuracy

Mold performance and durability depends on mold base quality, and hole making is a crucial step in the process.

Read MoreHand Scraping Craftmanship

Hand scraping is the process of using either a manually or motorized-driven scraping blade to remove very small amounts of metal from a precision surface to eliminate high spots left behind from the machining process.

WatchVMC Enables Faster, Smoother Cutting

Higher spindle speed and sufficient CNC look-ahead improve efficiency, tool life and surface finish in the manufacture of foam injection molds.

WatchCryogenic Machining Eliminates Moldmaking Conundrum

As moldmaking material gets harder and more expensive to cut, suppliers are “caught between a rock and hard metal,” balancing production costs with customer needs. Cryogenic machining with through-tool liquid nitrogen makes production of longer-lasting molds efficient and affordable.

WatchMachining Complex Contours

Advanced, integrated processor geometry eases processing and predicting of turn-mill contour operations and residual grinding stock allowance.

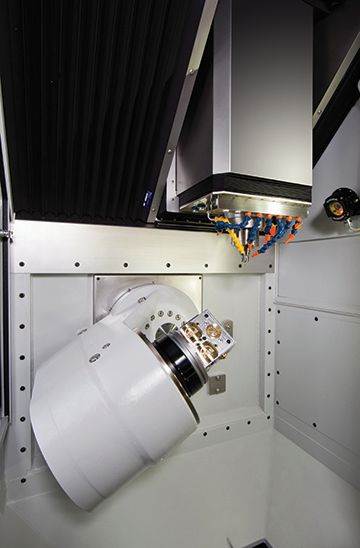

WatchProductivity Meets Precision

With machine dynamics, mechanical design and thermal stability in control, mold manufacturers can take five-axis machining to the next level.

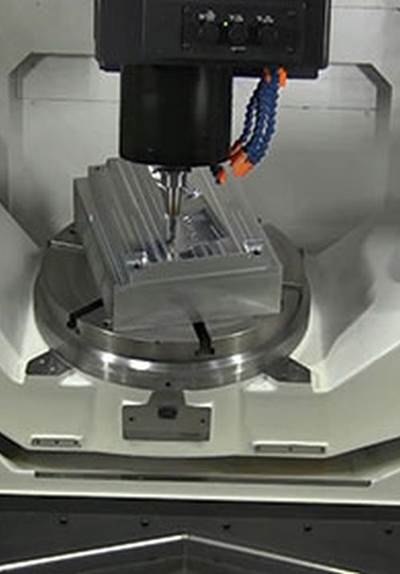

WatchIncreasing Five-Axis Accuracy

Probing and five-axis auto-tuning can correct machine misalignments in minutes, not hours.

Read MoreMaking the Complex Simple

Tool center point management streamlines five-axis programming and setup.

Read MoreMachining 3D Parts

For most of the 3D machining required in moldmaking, there are essentially seven steps necessary to achieve the desired results in terms of shape, finish and cycle time.

Watch

.jpg;maxWidth=970;quality=90)