Machining

Rethinking Three-Axis Capabilities

Ballnose cutters don’t necessarily require five-axis machining routines to impart fine surface finishes that don’t require hand polishing.

Read MoreWhat Machine Consolidation Can Mean for You

How to expand your production and profits in milling and high-speed cutting.

WatchInvesting More Than Finances Yields True High-Performance Machining

Batesville Tooling & Design is a family-owned company that manufactures complex injection molds. The company took its first step into high-performance machining in 2012 with a Makino F5 vertical machining center.

WatchBusiness Booms with Advanced Micro-Laser Welding Capabilities

Micro Tool Welding combines the science of laser technology with experience in tool and die repair.

WatchBetter Molds in Less Time with High-Technology Machinery

One of the most important contributors to its bottom line is Do-Rite’s latest addition, a new Creative Evolution FMC-1060 machine.

Read MoreThink Metric, Part 3

Insight from several technology suppliers—in design software, mold components, programming, machines, cutting tools and measurement equipment who have been following the metric trend—may help to make the transition a smooth one.

Read MorePreventive Maintenance Makes Good Dollars and Sense

By keeping up with your recommended preventive maintenance (PM) schedule, you can reduce your chances of having a catastrophic breakdown.

Read MoreHow to Tackle Sophisticated Molds

Considering that semi-finishing and finishing processes account for 70 percent of the milling of a mold, it becomes obvious that using such a system can lead to huge productivity gains.

WatchRaising the Bar on Better

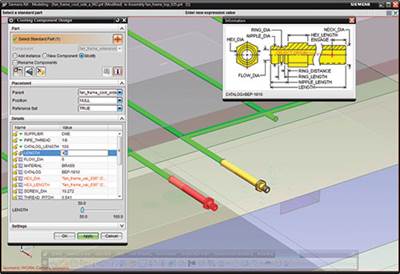

A look at one project to move away from traditionally customized moldmaking toward a level of complete automation that raises the bar on accuracy, repeatability and control.

Read More