Jig Boring for Mold Base Accuracy

Mold performance and durability depends on mold base quality, and hole making is a crucial step in the process.

The mold base assembly is the foundation of the mold and the molding process. A mold base positions and anchors the mold inserts, cavities and cores; incorporates cooling channels; and enables the mold to be opened and closed. The engineering and manufacturing quality of the mold base largely determines a mold’s performance and durability.

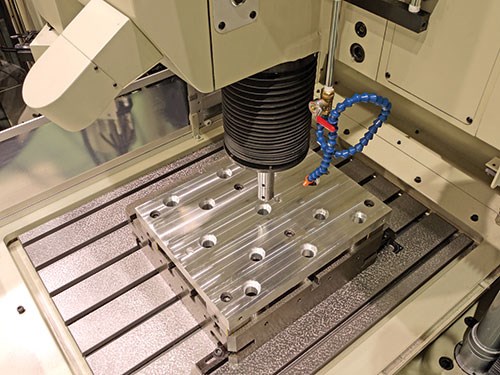

Hole making is a key manufacturing process, and any mold base will feature multiple high-tolerance bores for components such as guide pin bushings. The accuracy of those bores contributes to smooth and reliable mold operation. To maximize the quality

of the critical bores, many shops that manufacture mold bases finish them with specialized jig boring and jig milling machines.

Jig Types

Jig boring machines were initially developed in the early 1900s to machine fixtures (jigs) used to guide tools in precision hole-making operations. Later, manufacturers began to use the jig boring machines themselves to produce precision bores.

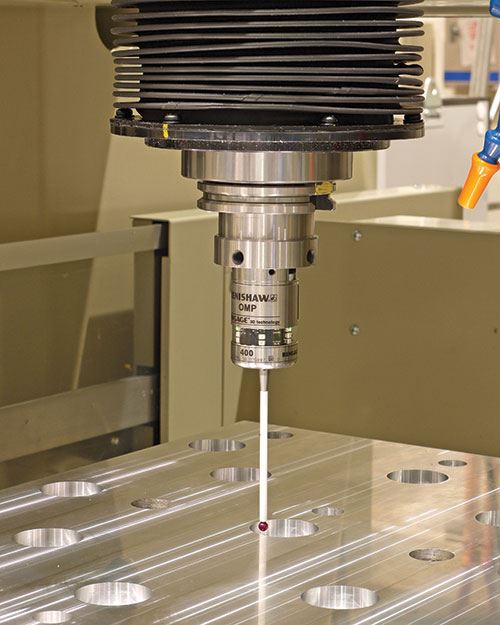

The machining tolerances for bores in mold base applications can be less than 5 microns in location, roundness, perpendicularity and straightness. To meet those requirements, a jig borer must operate at even higher precision. Positioning tolerances for the machines of 1 micron are not uncommon. The machine accuracy is such that some shops perform measuring operations with them in the same way they use coordinate measuring machines (CMMs).

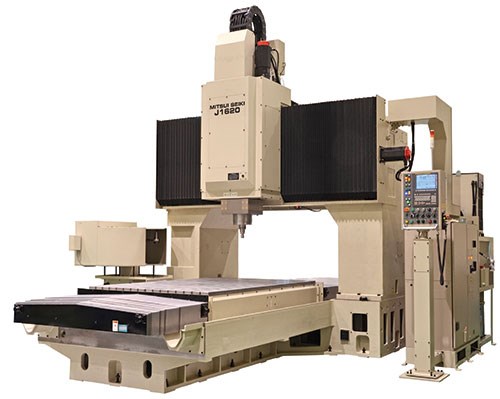

Jig boring machines are available in two basic configurations. In gantry-style machines, a boring quill rides a bridge between two supports, and the worktable moves the workpiece in one axis. In knee-style machines, the spindle moves vertically on a solid column, and the table moves in two axes. A moving table enables the workpiece to be precisely oriented in line with the cutting spindle, eliminating side loads and other effects of overhang. Unlike the boring process on a lathe, the part is stationary while the boring tool machines the bore to the desired size. The mass of the workpiece has no influence on the operation’s accuracy, an important consideration when machining a large mold base. A jig boring machine usually bores only the holes on a workpiece that require the highest level of precision.

While very similar to a jig boring machine, a jig milling machine adds a larger-capacity toolchanger and the capability to perform milling operations and other ancillary work that jig borers aren’t designed to handle.

Spindles in early jig boring and jig milling machines were vertically oriented. Horizontal jig borers and jig mills were developed later to fulfill different end-user requirements and preferences. The horizontal configuration can accommodate components whose size or shape prevent them from being processed on a vertical machine. The horizontal arrangement also can facilitate automation by enabling a part to be rotated 180 degrees for machining on both sides. In addition, gravity enhances chip flow when machining horizontally. However, gravity also can make fixturing and setting up a part on a horizontal machine more difficult and time-consuming, especially if the part is large.

Jig Features

Current global competition and astronomical volume requirements for some plastic parts have prompted manufacturers to build ever-larger multi-cavity molds that produce more parts in less time. The result is larger mold assemblies overall that incorporate larger mold bases. As mold assemblies grow larger in size, the effects of deviations in mold base dimensions are magnified.

The rigidity of the jig boring machine and its components affects the quality of the bores it machines and the productive lifespan of the machine tool itself. Larger mold bases can weigh 5 tons or more. Handling heavy weight and maintaining tight tolerances for critical mold base features requires a substantial machine tool structure composed of heavy castings. If structural strength is insufficient, weighty workpieces will push machine components out of alignment and cause premature machine tool wear as well as declining machining accuracy.

The guideways of jig boring machines are engineered to maximize geometric stability. Vertical jig boring machines typically have one V-profile way and one flat way on the table axis, with the V-way as the principal guiding way and the flat way as a load bearer. Double V-ways are used in all slideways of horizontal machines. V-ways are difficult to manufacture but provide precise management of machine geometry and motion. The sliding members are mated with needle roller bearings that are lubricated specifically to allow for extremely precise motion and minimal stick/slip.

Vertical jig boring machines usually have work strokes ranging to 40"x 60" (1 × 1.5 m) in size and generally are engineered to carry out high-precision boring operations only. In contrast, jig mills may have larger work capacity (ranging to 65" x 120"), and can use milling cutters and other tools to perform multiple operations in one setup. Jig mills also have higher-speed spindles and ground-tool-steel box ways to provide greater milling capability. Some jig mills offer linear motion slideway systems that facilitate high-accuracy machining.

The larger worktable of a jig milling machine can make it the only choice for processing some larger, heavier workpieces. A jig mill’s ability to perform operations other than boring may also eliminate the need to move a large workpiece to another machine, saving time and avoiding loss of accuracy during the transition.

Thermal stability of the machine tool is a key factor in maintaining bore tolerances. When results are measured in microns, even small temperature-driven changes in machine dimensions will significantly affect machining accuracy. Machine castings are engineered to provide stable thermal characteristics, and a typical jig boring machine will have components arranged symmetrically, so they will react to temperature changes evenly. For maximum accuracy and consistency, many shops operate their jig boring machines in temperature controlled-environments.

Jig Effects

The specialized nature of jig boring and milling machines results in their infrequent replacement. Effective life cycles of 25 years are not unusual. However, the mature technological capabilities of older machines usually require skilled personnel to produce parts with maximum quality. In addition, machine wear over time can affect the accuracy of the machining process. Shops should evaluate the output of their current jig boring and milling machines in terms of what is available with present-day technology. Look for machines whose capabilities are continually improving with advances such as ceramic ball bearings for spindles, four- and five-axis CNC operation, 0.0001-mm-resolution linear scale feedback, and new design and casting technologies to boost accuracy and productivity.

The mold industry is facing global competition on quality and price, and machines that offer the ability to increase output while improving accuracy are a driving force behind new investment in mold base manufacturing.

Related Content

Tips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

Read MoreDevelopments in High-Speed Machining Technology

There have been many exciting developments in high-speed machining relative to machining centers and controls, tooling and CAD/CAM systems.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=970;quality=90)