Machining

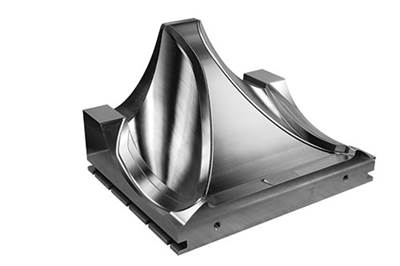

Smooth Surfaces without Hand Finishing

Advances in NURBS functionality speed up cycle times, meet high-accuracy finish requirements and allow molds to be completed on the machine.

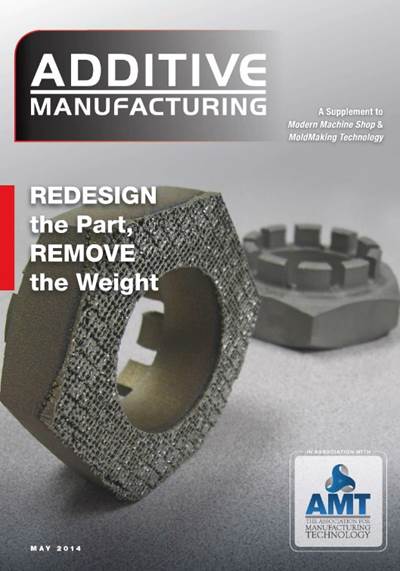

WatchDigital Ed. of MMT's May Additive Mfg. Supplement Ready

This month's edition features stories on how to push additive manufacturing to the next level with a commitment to customer service, education and training, as well as a look at one manufacturer's year-long journey with additive manufacturing.

Read MoreFive-Axis Myths

A look at the misinformation that prevents moldmakers from taking advantage of five-axis machining strategies to shorten total machining times.

WatchPlan Your Workholding for Improved Productivity

Choosing and organizing the right workholding can result in significantly improved machine efficiency, and it is essential for reaching any machine’s full potential.

Read MoreMetal Laser Sintering Hybrid Milling

Metal laser sintering hybrid milling combines metal powder 3D laser sintering with high speed milling finishing into one machining system.

WatchLaser Sintering and Milling Working Together

A hybrid manufacturing process offers mold builders an alternative method for making cores and cavities with time and cost savings and increased consistency.

Read MoreFrom Craft to Science

For this shop, efforts to adapt to technology that reduces the need for human labor have driven a fundamental and ongoing shift to a more standardized manufacturing process.

Read MoreAngling for “Big” Advantages in Automotive Tooling

This shop hopes to capitalize on growing opportunities in a different market by adding to its large-part machining capacity.

Read MoreBuilding a Mold in Fewer Setups

Current machine tool technology can reduce complex elements of moldmaking while increasing mold quality and accuracy.

Watch