Machining

Flexible High-Speed Mold Machining

Use this planning guide to identify the right double-column machining center to fit your mold machining needs.

WatchEnhanced Precision Drives Extreme Transition

A machine that reduces the need for recutting and benchwork laid the foundation for this shop’s shift from mold maker to mold manufacturer.

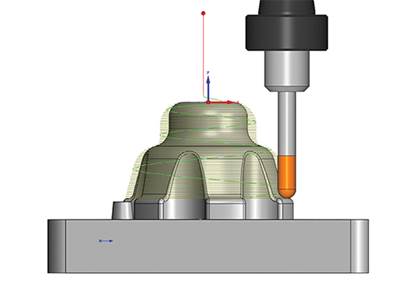

Read MoreSimplify Mold Machining

Use true five-axis simultaneous machining for your molds and inserts.

Read MoreAdopting a Production Mindset

An HMC with a pallet changer and modular fixturing system has streamlined job change-overs at this Tier 2 automotive toolmaker.

Read MoreNo Compromises for Large-Mold Machining

Two double-column bridge-type VMCs reduced this operation’s reliance on outside suppliers without requiring trade-offs between power and precision.

Read MoreA View from the Top Reveals Craftsmanship from the Ground Up

From atop the YCM Americas Inc. double-deck booth visitors can sit and enjoy a beverage and snack while taking in the 14 machines on display this year that showcase the latest vertical, horizontal and five-axis machining technology as well as the company’s unique strengths in manufacturing machines from the ground up.

Read MoreIMTS: Automate Your Way out of the Skilled Labor Shortage

GF Machining Solutions is on a mission this IMTS to help industry overcome the skilled labor shortage and stay competitive at the same time. Their solution is automation.

Read MoreInvesting in a Five-Axis Future

This shop’s first five-axis machine offers capabilities that exceed its needs—at least for now.

Read MoreBreaking Barriers Between Vision and Reality

For this OEM, speeding time to market required empowering its captive moldmaking operation with not only new technology, but the culture to use it effectively.

Read MoreTaking the Next Step Toward Five-Axis Efficiencies

This moldmaker’s latest five-axis machining center has improved cycle times and surface finish on certain parts while freeing older machines to process other work.

Read More