Machining

Amerimold 2017: Multitudes of Metalworking Materials and Machines

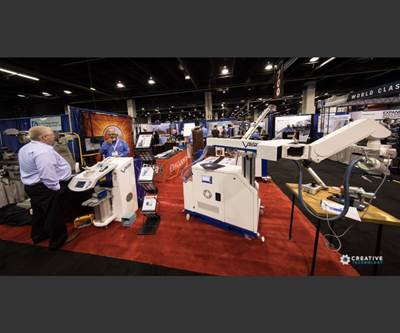

Amerimold proved once again that it is THE event for moldmaking.

Read MoreLearning About Machines and Systems Up Close

Amerimold 2017 had many new and different activities for attendees this year, including demos and presentations about machines and systems to help moldmakers optimize their processes and get higher-quality results.

Read More2017 Leadtime Leader Awards Winner: Graphic Tool Corp.

Leadership changes set this mold manufacturer on a path of renewed purpose, fueled by data-driven, lean methodologies and deliberate, quality-controlled production.

Watch2017 Leadtime Leader Awards Honorable Mention: Concours Mold Inc.

This Canadian mold manufacturer identifies teamwork and quality as critical to its ability to drive continued success.

Read MoreLaser Optimization Brings AM to the Next Level for Moldmaking

Metal 3D printer manufacturer Sodick first launched its OPM250L at IMTS 2016, where Phoenix DeVentures of Morgan Hill, California, showcased its success with the new hybrid machine.

Read MoreTechnology Tuesday – Amerimold 2017 Preview

Amerimold 2017 is only six weeks away, and it’s shaping up to be our largest Expo just for the moldmaking industry yet. Here's a preview of a few products and services you can expect to see there.

Read MoreMonitor Your Machines

If you manage or work on a shop floor, then you have likely heard about machine monitoring.

Read MoreSomeone’s Got a New “Kitty”

One company's investment in Kitamura machine tools keeps growing and business is growing along with it.

Read MoreThe Danger Zone

Spindle crashes can have costly consequences. Collision protection systems can help minimize the damage.

Read MoreMachinery Additions Accelerate Shop’s Growth

Six new Makino machines and updated processes allowed this moldmaker to penetrate new markets.

Read More

.jpg;maxWidth=970;quality=90)