Inspection & Measurement

Facing the Quality Challenges of Large, High-Precision Tooling

Advanced off-line inspection software speeds up mold manufacturing and assembly for aerospace giant.

Read MoreEvaluating Mold Quality

Quality is the name of the game in manufacturing. It’s not just about quality products, it’s about quality processes—from receiving to shipping, TQM, QA, quality service and delivery. Every facet of the manufacturing process has been assigned standards and how well those standards are met is an indication of the quality of that particular product, process or service. Quality products require quality materials, processes, equipment and tooling—specifically in the case of injection molded parts, quality molds.

Read More3-D Laser Scanning Opens the Door to Inspection And Reverse Engineering for Moldmakers

Next-generation scanning technology precisely captures large and small molds.

Read MoreDetecting Water Flow Restrictions

A look at how taking the time and data to analyze a mold problem will help you repair it right—and permanently—the first time.

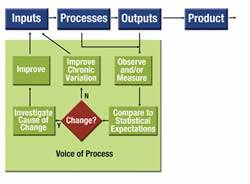

Read MoreStatistical Process Control: Beyond the Data

Statistical process control used correctly allows moldmakers to connect data sources, collect data and issue failure alarms in real-time.

Read MoreFive-Axis Inspection for Moldmakers

Does five-axis inspection offer similar benefits in speed and accuracy for moldmaking operations?

Read MorePortable Temperature Indicator Measures Mold Surface Temperature Quickly, Efficiently

A portable temperature indicator provides a quick readout of the actual surface temperature at the point of contact on a mold with an accuracy of +/- 2 percent.

Read MoreBadgering Mold Variability with On-Machine Gaging

Using unique on-machine metrology software helps to nail down injection mold machining consistency.

Read MoreWhy You Need to Inspect the Part to See the Mold

In the simplest terms, a good mold is one that makes good parts. When your customer is making good parts, no one questions the mold. It’s when the parts are not meeting spec that the mold—as one of the main elements of the molding system—is called into question. In these situations, one common proposal is to measure the mold to ensure that it conforms to the designed dimensions.

Read More