Inspection & Measurement

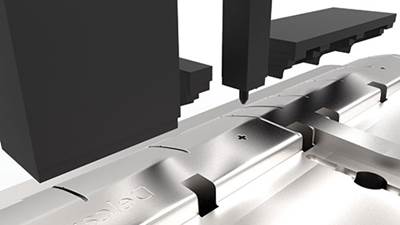

Integrating Electrode Production

How CAD/CAM can help make the design, machining and inspection of electrodes completely integrated.

WatchMega-Cell: Moldmaking Automation

The Mega-Cell is a production system that ties together all available opportunities to automate and control the process.

WatchRaising the Bar on Better

A look at one project to move away from traditionally customized moldmaking toward a level of complete automation that raises the bar on accuracy, repeatability and control.

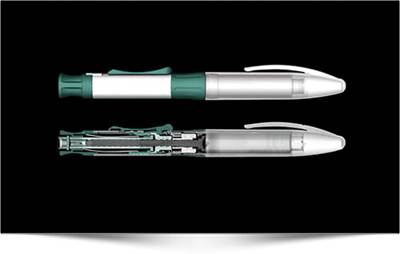

WatchInspecting Highly Complex EDM Projects with Industrial CT Scanning

Industrial CT scanning plays an integral role in the EDM process when it comes to inspecting small, highly complex, detail-oriented parts.

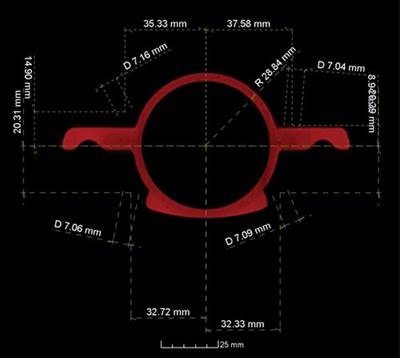

Read MorePairing GD&T with Industrial CT Helps with Moldmakers Part to Print Projects

Industrial CT scanning has become an integral part in GD&T and how the internal measurement of complex component parts should be facilitated.

Read MoreCMM Integral to Growth Strategy, Overall Capabilities

The appropriate strategy in precision measurement equipment additions helped YAMI satisfy customer quality and productivity levels. And the addition of future in-house mold building/repair/engineering capabilities will help serve their customer base even better.

Read MoreImprove Input Quality with the Right Tool Inspection and Monitoring System

Integrating efficient tool inspection before and after the cut with optimized tool performance in the cut improves mold manufacture’s efficiency and profitability.

Read MoreInspection/Measurement Advances Yield Better Molds Faster

A roundtable discussion of the latest trends and developments in mold inspection and measurement technology highlights the cycle time reduction, accuracy improvement and cost decrease benefits.

Read MoreInspecting Complex Product Profiles

Using metrology software and a portable CMM, mold manufacturers can efficiently handle exceedingly complex surface profile requirements.

Watch