EDM

Process Management Leads to Easier Automation

Before you move your shop into full blown automation, integrate a pallet system and process management software.

Read MoreHow to Choose and Size the Right Metalworking Filtration System

Understanding the importance of a properly engineered filtration system to the mold build process.

Read MoreMolding Success Through Automation

HSM technology helps U.S. moldmaker maintain world-class productivity and business growth.

Read MoreAccuracy Determines Quality in Electrode Manufacturing

A look at how electrode accuracy directly impacts the overall value of the mold build process.

Read MoreApplying Continual Process Improvement with the Right CMM/EDM Setup

Shifting coordinate-acquisition from EDM to CMM yields dramatic productivity gains.

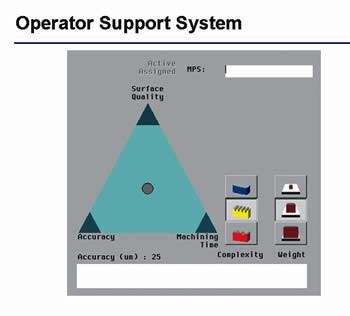

Read MoreSmart Machining: A New Development in High-Speed Machining

Improved process reliability, optimized machining performance and reliable unmanned operation are the results of smart machining implementation.

Read MoreIt’s Gut-Check Time for Tool Builders

It’s time to adapt or die as business evolution dictates development of new business and manufacturing approaches.

Read MoreExtreme Tool and Engineering: Building Relationships, Fostering Growth

This moldmaker proves that dedication to its customers combined with a will to thrive in a global marketplace is the right formula to win the MoldMaking Technology 2006 Leadtime Leader Award: Large Shop.

Read MoreA Double Whammy

The solution to solving problems associated with EDMing high copper alloy work metal involves finding the right graphite electrodes.

Read MoreMold Building Without Rule Breaking

Push the mold in the beginning of the build process to discover any weaknesses before it gets to the molder.

Read More