Accuracy Determines Quality in Electrode Manufacturing

A look at how electrode accuracy directly impacts the overall value of the mold build process.

In the fierce competition of the global market, U.S. manufacturers must continually find ways to reduce costs and leadtimes. Moldmakers must continue to evaluate the machining process regularly to keep their technology and processes most current for maximum efficiency and productivity.

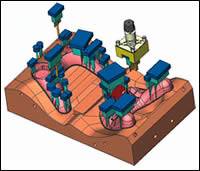

When it comes to properly manufacturing electrodes, more expensive isn’t necessarily better, but cheap is always cheap. Machine accuracy will determine how tightly a tolerance can be held. Higher accuracy and tighter tolerances will best preserve the integrity of an electrode’s true geometry.

Electrode accuracy affects every step along the way, from surface finish to burn time and overall leadtimes. Here is a closer look at some small ways electrode accuracy directly impacts the overall value of the mold build process.

EDM Burn Time

More accurate electrodes will decrease EDM burn times. If an electrode is off center, the following electrode will have to work harder to burn full-depth along one or two of the cavity walls. Uneven burning forces some electrodes to work twice as hard, extending overall burn time.

Electrodes that repeat evenly will duplicate the accuracy of the burn, eliminating uneven wear of electrodes. Consequently, higher electrode accuracy will require fewer electrodes to complete the burn and minimize the burn cycle.

Surface Finish

More accurate electrodes will allow finer surface finishes to be achieved. Electrodes that do not repeat will burn harder on one side of the cavity than the other, making it difficult to maintain fine finishes. In this case, a secondary process is often required to achieve smooth surface finishes while maintaining strict tolerances.

Secondary finishing techniques add time and costs to the mold building process, slowing throughput. Accurate electrodes allow finer tolerances to be used, requiring less hand work to achieve finer finishes.

Leadtimes

More accurate electrodes will reduce leadtimes by eliminating the need for secondary processes such as polishing. Shorter leadtimes allow moldmakers to turn jobs over more quickly, driving higher volumes and better profits.

Several variables can help achieve top accuracy in electrode manufacturing, including machine tool, control system, CAM system, graphite quality and cutting tools.

Machine Tool

There are several factors on a machine tool that can significantly impact mold building accuracy. Machine tools with a rigid design and heavy-duty cast iron construction deliver the best surface finishes because of the cut consistency achieved at all accelerations.

Reliable fixtures will add accuracy in electrode manufacturing. A well-designed fixture provides the same level of repeatability as the machine tool and holds extremely tight tolerances for fine finishing.

Toolholders can have a direct impact on machining accuracy. Although shrink fit toolholders are more reliable for balance and run out, a pre-balanced collet holder will hold the tightest tolerances, helping achieve the finest finishes and maintain superior mold geometries.

Control System

Another important machine tool element is the quality of its control system. A machine’s controls must be capable of processing large amounts of information quickly. Machine tools from a single-source manufacturer will ensure all elements of the control system work together for maximum speed and accuracy.

Program look ahead also is crucial to the overall accuracy in electrode manufacturing. The program must have enough look ahead for the control to adjust acceleration/deceleration without hesitation. Without adequate look ahead, gouging or over-step can occur. Look ahead allows the program to adjust machining speed, helping achieve superior contour accuracy.

CAM System

Software used in moldmaking is often application focused, meaning it is specifically designed for applications such as cavity design, electrode design and mold machining.

For top accuracy in electrode manufacturing, the software should be able to streamline the creation of toolpaths for fast and efficient machining, while preserving the high tolerances required in moldmaking.

CAM systems will assess a design’s manufacturability by detecting surface overlaps, twists, holes and undercuts. This allows parting lines and surfaces to be easily modified for preservation of the mold design’s integrity.

Graphite Quality

It is critical that the proper graphite grade be selected to meet the final mold design criteria, particularly for thin ribs and when electrode wear and metal removal rates are a consideration.

The quality of the graphite used in moldmaking can affect electrode fabrication time, the number of electrodes needed to complete a job, EDM time, accuracy of the cavity and polishing time. Factors such as flexural strength, particle size and microstructure influence the level of detail and surface finish that can be expected in the sinker EDM operation.

Cutting Tools

For moldmaking applications that require such high precision, quality and tolerance of the cutting tool is extremely important. A high-quality cutter will have closer tolerances on the radii on both a ball cutter and a bull nose.

Ball cutters are very versatile and therefore a good choice in these applications. They can rough and finish a wide range of materials. The tool’s shape helps achieve deep cuts and absorbs vibration to preserve accuracy.

Bull nose cutters require fewer passes and deliver better surface finishes. Because very little pressure exists between the cutter and the graphite, these cutters work well in moldmaking by achieving thin walls and ribs and very fine stepovers.

Summary

In order to stay efficient and maintain top precision in electrode manufacturing, it is important for moldmakers to first know how crucial electrode accuracy is to the overall mold building process. It is equally important to stay aware of how each machine variable can directly affect electrode accuracy.

Related Content

How to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreFive-Axis Graphite Mill With Automation Debottlenecks Electrode Machining

Five-axis electrode cutting enabled Preferred Tool to EDM complex internal screw geometry on an insert that otherwise would have had to be outsourced.

Read MoreIntegrated CAD/CAM Streamlines Electrode Manufacture, Improves Quality

A focus on electrode design and automation helps toolroom improve efficiency, reduce tooling costs and deliver higher quality products.

Read MoreRead Next

The Key to Better Electrode Making

Smooth out the process, eliminate unnecessary steps, reduce errors and automate repeat work by using a single software solution throughout electrode design and manufacture.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More