How to Choose and Size the Right Metalworking Filtration System

Understanding the importance of a properly engineered filtration system to the mold build process.

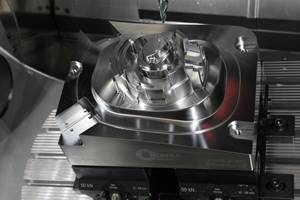

In today’s aggressive global market, modern moldmaking competition is fierce. You must deliver high quality molds on time at competitive prices. Just as the high-tech CNC equipment that molds are machined on must be state-of-the-art, the coolants and oils that are used in the various machining processes must be maintained to deliver quality parts on a consistent basis—the tolerance and surface finishes on part number one must be the same as part number 5,000.

The focus of this article is on filtration for coolant and oils used in the machining processes with emphasis on grinding. The objective is to increase throughput and maintain part consistency. Whether it is surface I.D., O.D. or cutter grinding, the quality of the coolant, oil and its cleanliness will have a direct bearing on the tooling, wheel and workpiece that is being machined to precision specifications.

Critical Coolant/Oil Functions

The coolant or oil that is used to cool the process in the grinding application serves these critical functions.

- Cooling the wheel and part from the heat that is caused by the grinding process, this controls thermal distortion which is critical especially with tight tolerances.

- Provides lubricity to the area where the wheel contacts the workpiece.

- Flushes away the removed stock as well as the abrasive that has worn off the wheel and carries these particles away from the workpiece back to the coolant tank, usually through a band or rolled media filter to catch the fines before pumping the process once again.

Coolant Challenges

The problem with this elementary type of filtration is that, at best, it only catches what you can see (the smallest particle the naked eye can see is 40 microns). It is what you cannot see that has a detrimental effect on your product and cost of machining. These particles are very small and are measured in microns—one micron is 0.000039 of an inch.

As your process continues, the concentration of these smaller particles becomes higher and you start to lose the effectiveness of your coolant. First you start to lose lubricity along with the effect of generating more heat at the cut, which increases wheel wear on the grinder, and in turn increases the need for wheel dressing that also adds fines to the coolant. The heat itself can cause the surface tension of the parent material to change showing noticeable stress cracks; therefore, causing the polishing and wear characteristics of the tool not to be uniform.

A Properly Engineered Filtration System

With a properly engineered filtration system the coolant life can be increased exponentially, which also is an environmental and disposal issue of its own. The wheel life is greatly increased and the machine tool itself is kept cleaner thus increasing the useful life of the machine.

Sizing a filtration system is an engineered process in which the size of the sump, the gallons per minute of flush rate and the heat load of the operation must always be accounted for. It is not a simple case of ordering a bag vessel from a catalog and installing it on the machine.

Filtration System Sizing

Type of Fluid

First and foremost, the type of metalworking fluid must be determined: neat oil, water soluble or synthetic water-based coolant. Once the fluid is established, the volume of coolant must be determined by the amount of flow (gallons per minute) needed at the process times six.

For example, a grinder flushing at 30 gallons per minute will require approximately 180 gallons of coolant. This may differ based on very light or very heavy stock removal.

Heat Exchanger

Stock removal also will affect the need for additional heat dissipation in the form of a heat exchanger. A heat exchanger can be as simple as a braze plate or shell and tube heat exchanger plumbed into an existing cooling tower in the facility, or to a stand-alone refrigerated liquid chiller. Sizing of such a unit is achieved by calculating the total number of BTU/HR that must be removed.

Cleanliness Level

Last, but not least, the proper method of filtration is determined based on the prescribed cleanliness level needed. Coolant filtration from one micron to 25 microns needs a medium to high-speed centrifuge or barrier filter (i.e., cartridge or rolled media filter is necessary); 25 microns and above can be achieved with centrifugal separation (no filter media); and, neat oils require a centrifuge or barrier filter.

Summary

When determining the type and size of the filtration system necessary for a new or existing machine, many factors need to be considered to select the correct filters and the best coolant. The final decision is based on the level of cleanliness and temperature of fluid necessary to produce parts on a consistent basis. Coolants and oils used in the machining process for grinding have a direct relationship to the quality of the machined parts. Only after the required quality of the produced parts is known can the correct system be installed. The selection of the filtration system is integral to the total machining process.

![]()

Related Content

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreTen Things You Need to Know about Circle Segment Milling

Considerations for evaluating if circle segment end mills or conical barrel cutters are right for your mold machining applications.

Read More3D Printing Enables Better Coolant Delivery in Milling Operations

Just like 3D printing enabled conformal cooling channels in molds, additive manufacturing is now being used to optimize coolant delivery in cutting tools.

Read MoreRead Next

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More