EDM

HSM Equals Accuracy and Precision at Less Cost

A California moldmaker makes the most of state-of-the-art machine tool and design technology to deliver competitive advantages for a medical device customer.

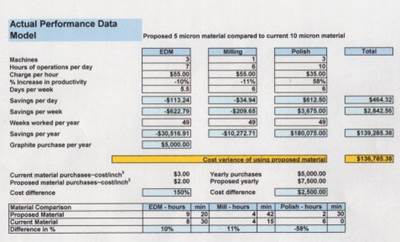

Read MoreTotal Cost of Ownership and Productivity Analysis for EDM

Using the graphite TCO model shows business owners how to save time and money in their EDM operation.

Read MoreDonna Koebel: Hands-on Leadership Gets Results

An industry veteran is properly recognized for a lifetime of hard work and success.

Read MoreGraphic Tool: Concurrent Engineering Generates Quick Mold Builds

Using the latest in technology and equipment concurrently adds up to sales aplenty - and an Honorable Mention in MoldMaking Technology magazine's Leadtime Leader competition.

Read MoreAdvance Tool, Inc. (ATi): Thinking Lean Gets the Green

Boasting clients like Microsoft, Procter & Gamble and Nokia, ATi's customer-driven attitude takes them around the world - and earns them MoldMaking Technology magazine's Leadtime Leader Award.

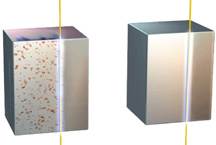

Read MoreThe Role of Graphite in a Quality EDM Finish

While many moldmakers believe that they can get away with lower-grade graphite if they have a quality EDM machine, in reality, the quality of graphite plays a much larger role in achieving the right EDM finish.

Read MoreElectrical Discharge Generator Breaks New Ground

A brand new EDM generator achieves a cutting speed of 400 mm}/min, or 37 square inch/hour, for the first time in the world, and achieves the feat of marrying the integrity of the surfaces machined with a high cutting speed.

Read MoreOffline Programming for Competitive Solutions

New EDM technology can improve cycle time reduction and enhance cost savings.

Read MoreInland Technologies Bucks Trend

A unique mold shop ensures quality, on-time delivery using technology as its key tool.

Read MoreHow to EDM Large Surfaces Through Diesinking

A new technology allows moldmakers to control the EDM process and to ensure a uniform surface finish.

Read More