EDM

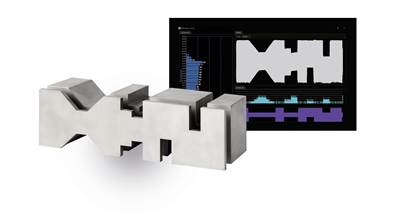

Spark Track Prevents Wire Breakage for Stable EDM Processes

GF Machining Solutions offers Spark Track technology for wire-cutting EDM.

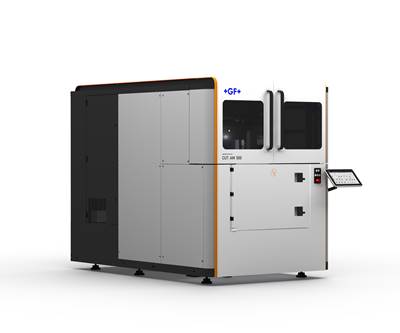

Read MoreEDM Speeds Up Additive Part Separation, Preserves Part Integrity

GF Machining Solutions announces the AgieCharmilles Cut AM 500, a horizontal wire EDM designed to complement metal additive manufacturing.

Read MoreDie-Sinking EDM Optimizes Micromachining Processes

GF Machining Solutions showcases the AgieCharmilles Form X 400 die-sinking EDM solution.

Read MoreDesign Capabilities and a Lean, Skilled Team Makes Do-Rite Die & Engineering a Valuable Source for Die Cast Dies

Do-Rite Die & Engineering’s skilled team knows how to achieve creating even the most complex details using EDM or a combination of electrodes and three-axis machining.

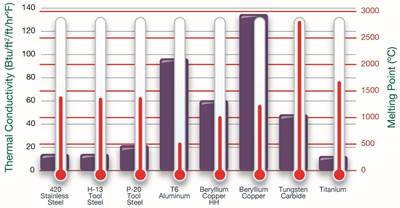

Read MoreHow to EDM Steel and Copper Alloy Simultaneously

A strategy for machining details when the part geometry falls across multiple workpiece materials.

Read MoreCutting Edge Strategies for Optimizing Milling and EDM

Makino Technology Expo focuses on high-precision machining and digital technologies to advance moldmaking.

Read MoreMakino Continues to Raise the Bar on Machining Technologies

Packed with information to help attendees advance moldmaking, and more, Makino’s Technology Expo shows the company’s commitment to its customers’ successes.

Read MoreShorten Cycle Times with Automatic Slug Removal

Automatic EDM slug management systems yield unmanned, lights-out operations, shorten cycle times and allow roughing and finishing operations with zero operator intervention.

Read MoreSodick Announces 2-Year Standard Warranty

EDM manufacturer Sodick revealed that it will now include a two year warranty standard for all premium model wire and sinker EDMs.

Read MoreMC Machinery Systems to Host EDM Training Event

MC Machinery Systems will be hosting a free technical training event for their EDM and milling equipment on September 10, 2019 at the company’s West Coast Technology Center in Cypress, CA.

Read More