A Low-Tech Solution for Cutting Moldmaking Costs

Machine-ready blanks have been available for decades, yet mold manufacturers have been slow to adopt them, even though they can save as much as 30 percent off overall mold and mold component costs and free up machine time for creating more in-house capacity.

Using machine-ready blanks (e.g., blanks that have been cut and precision ground on all six sides) eliminates the need to adjust setups and fixture offsets for each blank. In turn, this minimizes variation from part-to-part and increases part-to-part repeatability. Since the cost of machine-ready blanks is more than offset by labor and machine time savings, machine-ready blanks always reduce the overall cost of parts.

Benefits of Machine-Ready Blanks

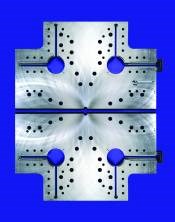

Typically, mold manufacturers begin with raw stock sawed to rough dimensions. Before it can be finish machined into a mold component or a mold base, it should be machined to exacting tolerances on six sides. Often to reduce cycle time and cost, manufacturers machine the top and bottom only. Later in the process, this causes additional non-productive time, such as resetting fixture offsets, tool changes and part handling time.

When purchasing a machine-ready blank, it should come to your shop at specified net, close tolerances—ready to load, lock and go. Machine-ready blanks need no further prep and very minimal setup time before beginning value-added finish machining. The time and cost that are saved can be up to 30 percent or more.

Many manufacturers do not want to pay the additional cost for a machine-ready blank, instead preferring to purchase raw stock, saw it and rough machine it in-house. Because in-house blanks are generally not as consistent part-to-part as machine-ready blanks, they result in additional time spent on resetting fixture offsets, additional part handling and tool changes. All of this time ends up costing the manufacturer substantially more, as much and sometimes more than 30 percent of the completed component cost. Plus machines are tied up performing non value-added operations, when they could be making more components and molds.

The reason making machine-ready blanks in-house takes so much time and costs more is because they require specialized equipment and processes (see Specialized Equipment for Machine-Ready Blanks sidebar below), which cannot be justified. Tolerances of some machine-ready blanks can be as close as ±.0005" dimensionally and ±.0002" flatness, squareness and parallelism. The specialized equipment includes double-disc grinders, Blanchard grinders and duplex milling machines.

Example

Just one of many benchmarks demonstrating the cost savings that can be achieved by using the right machine-ready blanks involves a part made out of aluminum.

| Rough-Blank | |

| Material: | 3/4 X 9 7/8 X 16 3/8 (Oversize) |

| Quantity: | 100 pcs |

| Prep Machining: | 11.12 min |

| Operator Intervention | 15 min |

| (such as changing clamping) | |

| Finish Machining: |

54.83 min |

| Total Run Time: | 81 min |

|

Machine-Ready Blank |

|

| Material: |

.625 X 9.700 X 16.250 |

| Tolerances: |

+/-.001" Thickness, +/-.002" W/L |

| Flatness: |

within .002" |

| Quantity: | 100 pcs |

| Prep Machining: | 0 min |

| Operator Intervention: | 0 min |

|

(such as changing clamping) |

|

| Finish Machining: |

54.83 min |

| Total Run Time: | 54.83 min |

| Machining cost savings: |

$40 per part |

| Material increase: |

$30 per part |

| Total cost savings: |

$10 per part |

| Total job savings: | $1,000 |

| Throughput increased: ≈26 minutes per part or 43.3 hours of machine time freed up for other jobs | |

In the example, a machine-ready blank eliminated 11.12 minutes of time spent premachining a rough blank and 15 minutes of operator intervention time spent making five clamp changes. Machine-ready blanks saved $1,000 over the cost of the job—even though purchasing machine-ready blanks cost slightly more than beginning with raw stock. Plus the total amount of machining time saved by using machine-ready blanks in this application increased capacity by freeing up a week of production time on one machine for more jobs.

Summary

Ever since mold manufacturers awakened to find competition from places such as Canada, Eastern Europe, Mexico and China, they have sought technologies that would allow them to compete with cheap labor. Mold manufacturers are using lean practices and limiting bids to projects that match their special expertise. While technology has helped cut costs, there are many decades-old, low-tech solutions that can reduce high labor costs and increase productivity. Machine-ready blanks provide substantially reduced costs and increases in throughput.

Related Content

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreRead Next

Rebuilding Tools with High Performance Material

High-performance alloy offers a unique combination of thermal conductivity and strength—providing numerous benefits to the moldmaker and molding process.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More