Cost of Ownership: A Lifetime of Molding Savings

“There’s nothing more expensive than a cheap mold,” has been said by many a tooling engineer after a bargain of a mold began bleeding profits.

Often, in order to decrease tooling costs, a long-established design approach is specified for several mold builders to quote, and the lowest bid wins. However, a different mindset could yield much greater savings not only at the mold build and initial production launch, but also over the lifetime of the tool.

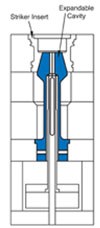

An area in which there is opportunity for lowering tooling costs is with alternatives for round undercut release. Doing the math can show dramatic savings for high production molds when side actions are able to be eliminated, and experiences from the field support this point.

It Begins in Quoting

An RFQ is received and the customer is accustomed to side action molds for their particular niche. They’ve always done it that way! But before quoting it in the same manner as the rest of the pack, there may be alternatives.

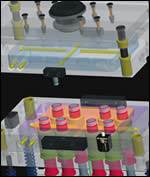

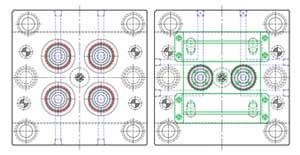

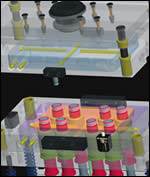

Figure 1 shows the result of laying out a mold with two different approaches: side action tools versus expandable cavity tools. The mold cost will be competitive; however, the big savings comes from the cost of ownership over the lifetime of the tool.

Higher cavitation per mold results in more parts from the same press as a side action tool. For example, an 8-cavity slide mold with two columns requires the same width base as a 16-cavity, 4-column expandable cavity mold. Or, an 8-cavity tool without space consuming slides is six inches smaller in width and can run in a smaller press. Either way it is looked at, profitability is gained hour after hour, throughout the mold’s life.

But that viewpoint must be called out early; otherwise the same old same mold will be built once again, and opportunities for evolved profitability will have been overlooked.

All Things Considered

Michael Montagna and Bryan Hull at Mier Tool Company (Auburn, NY) saw the big picture and provided the benefits to their customer.

“Taking into consideration the costs involved with all the tool work required for slide sets, we suggested utilizing expandable cavities, which would not only eliminate the slides but also the manufacture of heel pockets and other associated components,” Montagna says. “The mold features needed to accommodate the expandable cavities were much simpler to machine in the mold core insert and the pin plates.”

In addition to these advantages, another one reveals itself, and that is in the mold design. It is more straighforward and simplified—a time saver for designers, as well as the toolroom personnel who will maintain the mold over its lifetime.

There can be a cycle time advantage as well. Kleber Salazar from Marland Mold (Pittsfield, MA) found that “simplification of mold designs with less moving parts allows for easier maintenance, but most importantly, it allows for enhanced cooling, and consequently lower cycle times and higher output.”

Doing the Math

Even if eliminating side actions were to add to the tool cost, a favorable return on investment could be calculated.

With a more compact and efficient mold design, significant savings can be realized. Due to a lower hourly press rate, moving down a press size and reducing maintenance time on a 16-cavity mold running 10M parts per year could produce savings of more than $40,000 per year. Also, more efficient cooling can potentially reduce cycle times by 5 percent, resulting in as much as $10,000 in additional savings per year.

Over 10 years ago John Hahn and the team at MGS MFG Group (Germantown, WI) selected expandable cavities when bidding for a program of several 24-cavity and 48-cavity molds that would run in the U.S., Mexico and China. “We saved space with expandable cavities, leading to more parts manufactured within a smaller press,” Hahn comments. “We didn’t even need to do a formal ROI cost justification; it just made sense.

“As for reliability, the tools have been running since 1996 and have over 10 million shots,” he continues. “The program was clearly a success due to a creative, cost-effective approach.”

Salazar at Marland concurs, saying, “A good way to continue adding value to our products is by partnering with companies which also embrace innovation. In working with expandable cavities, we have found a reliable alternative to traditional slide molds that help us reduce our mold base size, thus increasing cavitation with enhanced utilization of existing presses and no demands for expanded footprint.”

Profitable Investment

Moldmakers truly serving their customer might not simply obey the initial RFQ, but at times propose and prod for alternatives. After all, it’s a tool that will serve as an investment, and early on there are opportunities to deliver a continually more profitable yield.

Related Content

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreWhat is Driving Mold Lifecycle Management Digitalization?

OEMs are looking to partner with suppliers to share and track data across the supply chain for advanced intervention and process management.

Read MoreEditorial Guidelines: Editorial Advisory Board

The Editorial Advisory Board of MoldMaking Technology is made up of authorities with expertise within their respective business, industry, technology and profession. Their role is to advise on timely issues, trends, advances in the field, offer editorial thought and direction, review and comment on specific articles and generally act as a sounding board and a conscience for the publication.

Read MoreRead Next

Don’t Build the “Same Old Same Mold”

Steps for evaluating the latest mold innovations in order to move along the evolution process.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More