Build

Weldless Technology Eliminates Weld Lines on Molds

A new patent-pending process that eliminates weld/knit/parting lines of molds has been developed by a consortium of alliance partners.

Read MoreImprove Shop Competitiveness With Five-Axis Capability

The key to keeping work local, while still remaining profitable, is a willingness to evaluate and dramatically alter your shop’s processes by investing in new technology.

Read MoreHigh-Speed Machines Deliver Speed, Accuracy, Repeatability and Finish

The addition of high-speed machines that blend a reasonable cost with high performance helps one moldmaker realize a huge competitive advantage.

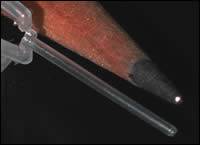

Read MoreMicromoldmaking: It’s a Small World After All

A great deal of attention needs to be paid to the design and build process—as well as post-moldmaking processes—when making molds for tiny parts.

Read MoreGet the Most from Your Tooling Investment

Alignment, mold protection, tonnage distribution and injection control are the main elements in the molding machine that could affect your tooling investment.

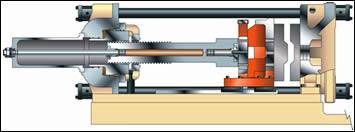

Read MoreDispelling the Misunderstanding About Small Fittings

It is not always immediately obvious how much effect your choice of pipe tap and water-fitting sizes are having on mold performance.

Read MoreCleaning a Flashed Hot Manifold, Part Three

Cleaning nozzles and manifolds, electrical boxes, assembly and final check.

Read MoreGetting the Most from Your Multi-Axis Machines

The growing importance of simulation and verification of CNC machining processes.

Read MoreHow to Choose and Size the Right Metalworking Filtration System

Understanding the importance of a properly engineered filtration system to the mold build process.

Read MoreConcept Mold & Die: A Bright Idea

This moldmaker empowers its employees and wisely invests in technology to ensure its survival for the long haul.

Read More