Improve Shop Competitiveness With Five-Axis Capability

The key to keeping work local, while still remaining profitable, is a willingness to evaluate and dramatically alter your shop’s processes by investing in new technology.

|

When examining the ramifications of the globalization of business, it is impossible to talk about manufacturing without discussing labor costs in Southeast Asia and third-world countries. The substantially lower wages of these regions have given them a distinct advantage in the manufacture of products in many industries. To succeed in spite of this challenge, American manufacturers need to pursue a course of action that minimizes, if not outright eliminates, the advantage of low-wage nations. This can be accomplished most effectively by employing strategies that take the labor out of production. Moldmakers in particular are highly susceptible to the cost of labor. Plastic injection molds require high levels of surface finish, beyond what can typically be obtained with a traditional three-axis machining center. To obtain the needed quality of surface finish, the components are usually machined and then subjected to lengthy hand polishing operations. This significant quantity of benchwork causes the cost of molds to be very sensitive to local wages, putting U.S. manufacturers at a disadvantage. While significant, the challenge facing American moldmakers is less than that facing their Western European counterparts, where the cost of labor is even higher than in the U.S. Despite this hardship, a large percentage of European manufacturers have managed to keep their work local, while still remaining profitable. The key to doing so has been a willingness to evaluate and dramatically alter their processes by investing in new technology.

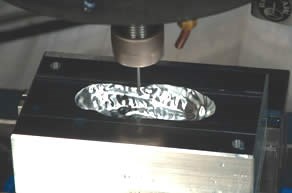

The Five-Axis SolutionApproximately 10 years ago, a handful of European moldmakers took interest in innovative five-axis machining centers. Compared to otherwise similar three-axis machines, the five-axis machines achieved a much finer surface finish. In turn, this eliminated much, and sometimes all, of the post-machining benchwork from the manufacturing process. By taking the labor out of parts, these European companies regained a level playing field against competition from low-wage nations. Over the past decade, an increasing number of manufacturers have witnessed the successes of five-axis machining and now the process is commonplace throughout much of Europe. To understand the benefits of five-axis machining, one must first recognize the key inherent weakness of three-axis machining processes. During milling operations, the tool cuts at the programmed speed at the periphery of the tool, but the cutting speed drops to zero at the center of the tool. When machining a cavity in a mold component, the limited range of motion in a three-axis machining center makes it impossible to fully control the point of tangency between the tool and workpiece. This means that cutting conditions are constantly changing as the mill moves through the programmed toolpath. As a result, it is impossible to achieve a consistent surface finish throughout the whole of the part, causing the need for hand polishing after machining. With a five-axis machine, the pro-grammer gains control of the angle at which the cutting tool meets the workpiece. By programming the machine correctly, constant cutting conditions can be maintained over the entire part, resulting in a high quality, uniform surface finish. While the reduction or elimination of benchwork provides the most significant benefit, five-axis machining also provides other, ancillary benefits. When cutting with a traditional three-axis machine, as the point of tangency between the tool and workpiece approaches the center of the tool, the reduction in cutting speed decreases cutting efficiency and increases cutting forces. The resulting higher tool deflection shortens tool life and increases the probability of fracturing the tool edge. Consequently, using a five-axis machine to control the point of tangency and cutting conditions provides for significant improvements in tool life. Nearly all moldmakers can improve their efficiency by integrating a five-axis machining center into their operations, but some will reap greater rewards than others. Those producing large plastic injection molds with complicated cutting geometries stand to benefit the most. It is not unusual for this type of component to require as much as 40 hours of benchwork for finishing and, in extreme cases that number can double. With five-axis machining, this hand polishing can be virtually eliminated, reducing component cost by the equivalent of a full week of man-hours or more. Additionally, the integration of lathe operations in the latest high-performance five-axis machines offers the potential for even greater benefits to certain moldmakers. Those producing bottle molds or other components requiring both milling and turning operations can now machine total parts in one setup. This reduces the risk of inaccuracy caused by multiple setups and also eliminates the wait time between operations—allowing for higher flexibility and shorter response times.

Leveling the Playing FieldIn the recent past, American moldmakers have been at an increasing disadvantage to manufacturers operating in geographic regions with low labor costs. The key to reversing this trend lies in taking unnecessary man-hours out of production. Through the adoption of five-axis machining, it is possible for American moldmakers to even the playing field and achieve success in the global market. |

Related Content

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreRead Next

Improved Profitability through Process Improvement

Hard milling, automation and magnetic workholding are a winning combination.

Read MoreMachining Molds with Negative Stock Shutoffs

Negative stock shutoff can help you make better molds in less time. Here is a clear definition and description of the process. While the concept is fairly simple, the implementation can be challenging.

Read MoreMaking the Transition to High Performance Machining Techniques

Implementing HPM techniques—such as hard milling—into component production can be straightforward with the correct process and other considerations

Read More