Build

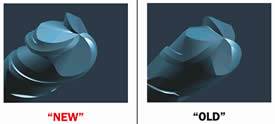

Minimal Investment In New Tooling Tech Increases Productivity, Tool Life and the Bottom Line

Having a fundamental base of the facts makes it easier to detail how some of the latest innovations in cutting tool substrates, geometries and coatings can make it easier for one’s moldmaking process to go from fast to furious.

Read MoreTech Tool & Mold, Inc.: Strength and Flexibility

This moldmaker garners the 2007 Leadtime Leader Award: Small Shop by being flexible with its customers, going lean, competing globally and uniting with other moldmakers.

Read MoreTooling Boards Offer Uniformity/Stability in Prototyping and Tooling Applications

A very uniform, dimensionally stable, urethane-based series of tooling boards has been developed for use in prototype, composite tooling, foundry pattern, fixture and other applications.

Read MoreDon’t Build the “Same Old Same Mold”

Steps for evaluating the latest mold innovations in order to move along the evolution process.

Read MoreHow to Achieve Economical Five-Axis Milling

Although moldmaking has not had great incentives to invest in five-axis technology like the aerospace industry, there are still many reasons for moldmakers to adopt five-axis machining, and there are a few interesting software functions that help to make five-axis programming economical.

Read MoreJig Grinding, EDM or High-Speed Milling?

When evaluating new processes for mold manufacture, jig grinding is worth a second look as machine manufacturers have now added high accuracy features to guarantee repeatable results.

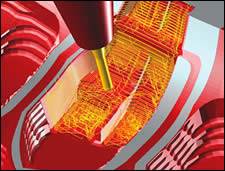

Read MoreCustom Moldmaking Process Technology Slashes Processing Time and Costs

A breakthrough molding technology has been developed that delivers considerable time reductions and cost savings for fabricators of parts constructed from composite materials.

Read MoreWorldwide Review and Analysis Of Additive Fabrication

Additive fabrication technologies can save significant amounts of design and manufacturing time when used properly.

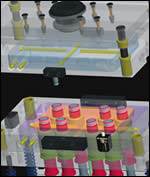

Read MoreHot Runners Shrink Leadtimes, Cut Costs

Standardized hot runner system allows the moldmaker to easily configure a system in just two weeks.

Read MoreThe Moldmaker’s Role in Controlling the Molding Process

How the toolmaker/mold designer can make the best choices when it comes to in-mold cavity sensing and control; how to do a good installation; basic functionality of the sensors; and, post installation care.

Read More