Build

Advances in Hot Runner Systems Drive Innovations in Part Engineering and Styling

Design and performance capabilities of components fabricated in state-of-the-art molds enhance the appeal of new vehicles.

Read MoreHigh Speed Balancing Act

Think you’re using toolholders properly balanced for high-speed machining? Well, you may have to think again.

Read MoreCemented Tungsten Carbide Offers Wear and Corrosion Resistance for Tooling

Using cemented tungsten carbide as a tooling material for core pins—especially in areas of high wear—can significantly reduce downtime.

Read MoreEvaporative Cooling Approach To Mold Temperature Control

This new mold temperature control technology allows tool designers to create mold designs engineered to a level previously unattainable.

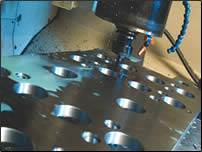

Read MoreFive-Axis Machining Is a Key Requirement for High-Precision Molds

Design and fabrication capabilities of advanced tool-cutting processes give toolmakers an edge in developing new business.

Read MoreHow to Make “Quick-Turn” Your Shop’s Mantra

On top of increasing production capacity, quick delivery standards save as much as five hours per project for a manufacturer of quality “quick-turn” tooling.

Read MoreRapid Prototyping/Rapid Tooling: State of the Industry

A look at the market for additive fabrication (also known as rapid prototyping) as it continues to grow.

Read MoreHow to Select the Correct Heater Insulation Material

Understanding why insulation is a key to heater life and performance.

Read MoreAutomation and Moldmaking: Mold Production in Action

Moldmakers are starting to change the way they think and incorporate automation into all aspects of their operation—combining a multitude of processes in a single cell for optimal productivity.

Read More