Build

Improving Sequential Molding

For large injection-molded parts, a servo-driven valve gate system can improve surface finish and part performance.

Read MoreUsing Data to Improve Mold Performance

An easy way to get a snapshot of how a mold is operating is to run regular mold scans via a hot runner temperature controller.

Read MoreProving the Advantages of a Servo-Driven Valve Gate System

One innovation for improving sequential injection molding centers around the use of servomotor technology.New servo-driven valve gate systems incorporate a toggle-type mechanism that operates the valve pin position at 90 degrees from the servomotor stroke.

Read MoreLegacy Precision Molds Aims for Ingenuity in Every Job

This Michigan moldmaker strives to deliver quality molds through ingenuity, "nimbleness" and a dose of home-grown integrity.

Read MoreBalancing Act

Consider elements of the entire tooling assembly, including the tool, holder and holder components, to optimize productivity.

Read MoreLooking for Ways to Reduce Energy Costs?

Then consider areas in the machining processes that unnecessarily consume energy. For example, machining center idling, unnecessary pump rotation and continuous running of peripheral equipment. Managing these areas can save a shop a lot of money. This is the subject of a white paper I came across recently that reveals how shops can achieve significant energy savings using the right CNC control to reduce power consumption during machine operating and waiting times.

Read MoreTMA Celebrates Distinguished Members at 90th Annual Meeting

A little over a week ago, I attended the Technology and Manufacturing Association’s Annual Meeting during which awards are bestowed on distinguished members for their work on behalf of the TMA and the manufacturing industry as a whole.

Read MoreAnother Look at EDM Generator Technology

Advancements in fully digital sinker EDM generators offer benefits in mold maintenance, process efficiency and electrode wear.

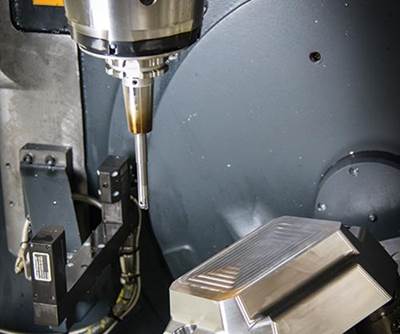

Read MoreFeatures and Functions of Five-Axis

Capitalizing on its unique characteristics can help you fully realize the potential of five-axis machining.

Read MoreRough and Tough

What you don’t know about high-efficiency roughing versus high-speed roughing could be costing you money.

Read More