Build

SLIDESHOW: Technology Showcase, MMT Surprise

This week's slideshow is an MMT 'Surprise' Showcase, editor’s picks for the week.

Read MoreThrowback Thursday: Improving Ejector Plate Alignment

Some concepts are worth a second look like this new alignment system that is said to be able to provide a more reliable mold by reducing wear on the moving ejector components.

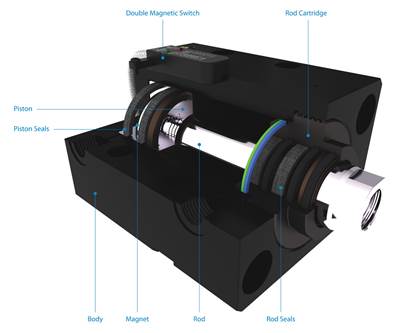

Read MoreCaring for Hydraulic Cylinders

Preventive maintenance on these important components will help keep a mold running.

Read MoreAchieving Maximum Cutting Tool Life

Getting the most from cutting tools requires high performance from all elements of the entire cutting system.

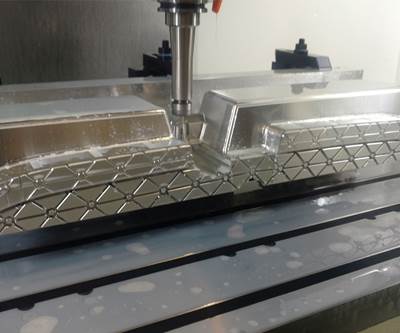

Read MoreFaster Cornering in Cavity Hogging Boosts Capacity

With a cutter capable of plowing through the corners at full speed, a Michigan moldmaker says it has doubled rough-milling throughput, freeing up machine time for mechanical polishing instead of tedious handwork.

Read MoreA Low-Cost Approach to Machine Monitoring

Retrofit technology allows a shop to outfit existing machinery with the ability to collect and relay data remotely.

Read MoreMTD Micro Molding

This shop specializes in building molds for tiny parts with such complexities as 0.1-mm walls, 0.025-mm corner radii and holes as small as 0.051 mm in diameter.

Read MoreLarger VMCs Allow Small Shop to Go Bigger

Two Kitamura machines immediately gave this Michigan shop the ability to win jobs that were previously too large to even bid on.

WatchKeeping the EDM and Holiday Lights Burning

With Christmas right around the corner, some holiday spirit found at Industrial Molds Group inspired this blog.

Read MoreUnderstanding Self-Lubricating Components

Recognizing that they are essentially conventional components with lubricant added in the form of graphite will help the molder realize their significant benefits.

Read More