A Low-Cost Approach to Machine Monitoring

Retrofit technology allows a shop to outfit existing machinery with the ability to collect and relay data remotely.

Many shops may be intimidated by the cost and complexity of implementing a smart machine-monitoring solution, as many of these systems require extensive resources, time and training to get up and running, and sunken costs often rise before the system can provide any benefits. Small and medium-sized enterprises, including mold builders, are looking for ways to break down the barriers to achieving true data-driven manufacturing.

Monitoring your facility remotely in real time shouldn’t be an intimidating process. Deep analysis of your shopfloor equipment costs time and money, but solutions are starting to emerge that offer quick, at-a-glance equipment analysis for a fraction of the cost of more extensive monitoring systems. Behold the retro-fit solution. Rather than buying new data-driven machinery, implement a solution that revitalizes the equipment you already have.

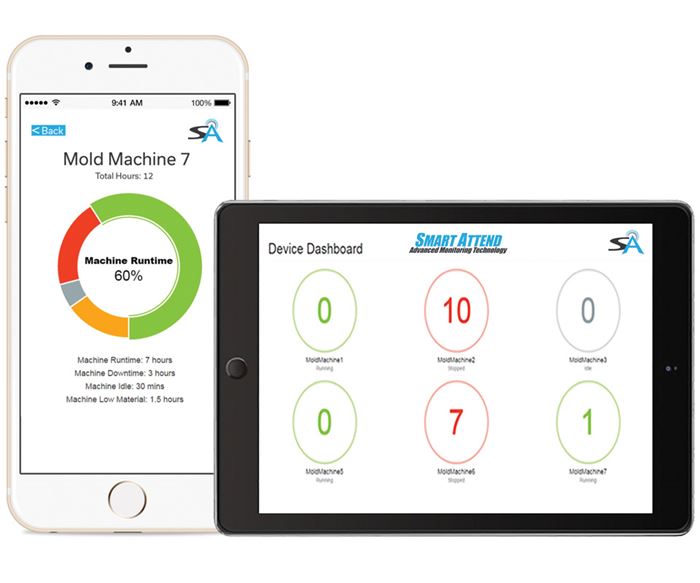

The idea is to use existing equipment and translate alarm signals into user-friendly presentations that can be easily understood by non-experts, and make this information remotely available and accessible from any location. The key to this new retrofit technology is outfitting your existing machinery with the ability to collect and relay data remotely, so you can see exactly where and how you need to improve.

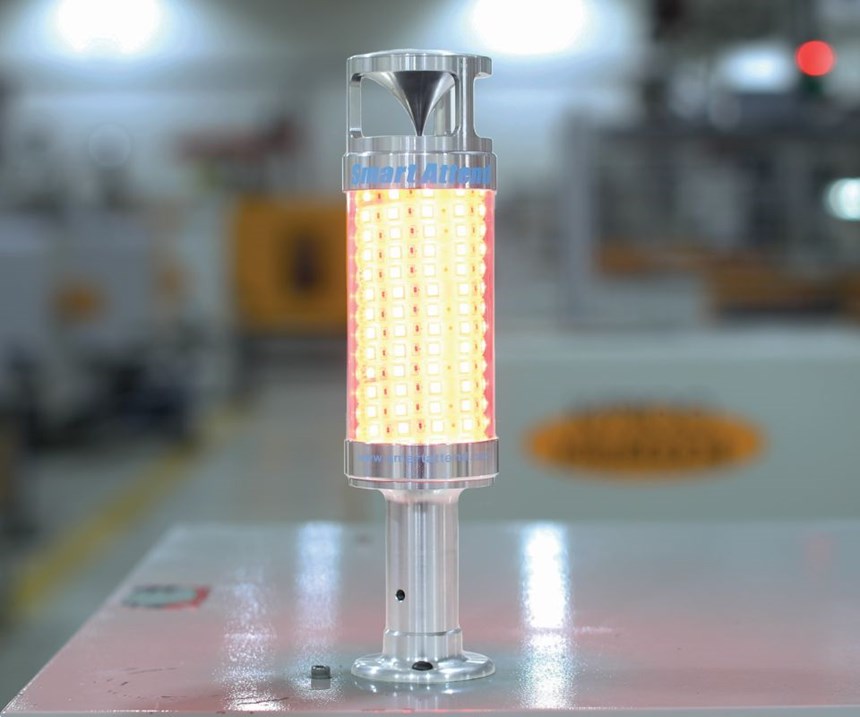

The real advantage of data-driven technology comes from the ability to use data that you already collect. Capturing that data can be a difficult task, but newer technologies and software are making it easier. For example, a machine can send pre-configured on/off signals and inputs to its installed tower light. Intelligent software then can translate these signals to provide an accurate display of what’s happening with the shopfloor equipment. Basically, this gives a perfectly operating, decades-old machine the ability to monitor its run time; calculate its efficiency; and accurately report on its downtime, idle time and alarm time. Also, an operator can instantly and at a glance view a machine as it operates and determine the length of time it took staff to respond to signals, minimizing machine downtime. With a low cost of acquisition, such intelligent software enables a shop floor to be viewed anywhere, at any time by a team assigned the responsibility of analyzing the facility in real time and making effective decisions on the fly.

Each shop floor will look for different signals and will analyze its production in a number of different ways. The key to effectively implementing a monitoring system is discovering a solution that provides the right easy-to-understand communication method and the information needed for the shop to create the most effective strategies. Machine-to-machine communication is the key driver of Industry 4.0, and the benefits of having a view of the entire shop floor at once from your phone or tablet can be an immense benefit for improving your shop’s efficiency.

Related Content

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

.jpg;maxWidth=970;quality=90)