Achieving Maximum Cutting Tool Life

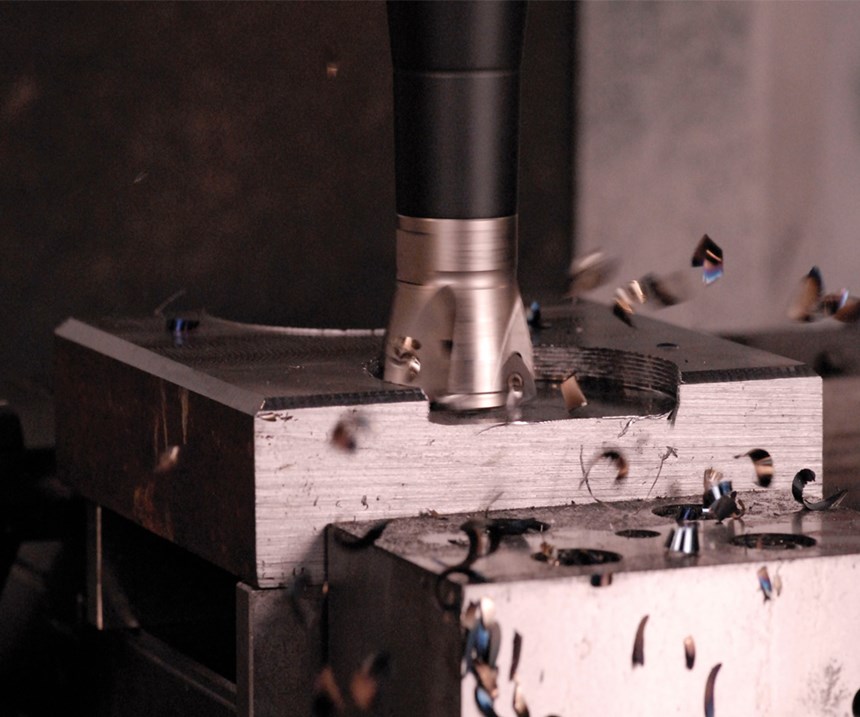

Getting the most from cutting tools requires high performance from all elements of the entire cutting system.

The benefits of prioritizing expected tool life over price when choosing metalcutting tools are clear, especially in the precision-focused and deadline-driven moldmaking industry. Reputedly, economical tools often provide abbreviated and unpredictable life that results in poor tolerance control and leads to expensive rework.

Considering that the investment in tooling represents only about 3 percent of the total cost of producing a part, the few dollars saved by opting for the least expensive tool pale in comparison to the hundreds or perhaps thousands of dollars lost in rework. In addition, higher performance tooling usually permits application of more aggressive machining parameters that boost productivity, free up machine time and enable more work to flow through a shop. When tools last longer, fewer need to be purchased and preset, and they occupy fewer places in the machine toolchanger. Consequently, tools that reliably hold tight tolerances over a long period of time facilitate untended machining that reduces the fixed cost of labor.

The practical value of improvements resulting from a change to higher-performance tooling depends to an extent on the manufacturing industry involved. Implementing new tooling in an ongoing critical aerospace or medical manufacturing operation has to produce savings large enough to outweigh the costs of documenting and revalidating an already-existing operation.

Tool cost is not an overriding factor in moldmaking. The key concern when machining mold components is the ability of the cutting tools to produce tight tolerances and fine surface finishes. Achieving specified dimensions is crucial. Surface finish requirements can be met in post-machining operations such as polishing, but the more precise the results from the machining operations, the less labor-intensive polishing is required to create the desired finish. Tools that provide accurate results over an extended period of time address both part dimension and surface finish issues.

The Cutting System

High-performance tools, however, do not operate in a vacuum. Ideally, they are part of a system that includes the machine tool, toolholding and workholding equipment, as well as programming software.

Similar to considerations of tool cost and performance, an investment in a premium machine tool pays off in machining consistency. Reliably achieving the tolerances common in contemporary moldmaking with a bargain-level machine tool is difficult, if not impossible. The time and money spent trying to meet desired dimensions or reworking defective parts outweighs the higher initial cost of a top-level machine tool. Overall machine rigidity and accurate, backlash-free axes produce true toolpaths and protect the tool itself from vibration damage. High-quality toolholding and workholding components serve similar purposes.

Use of appropriate advanced machining software also contributes to tool life and effectiveness. A poorly chosen CAM program will destroy even the most advanced tool. For example, it is important to program cutting parameters that maintain recommended chip thickness throughout an operation. When chips are too thin, the tool rubs the workpiece and generates heat that causes rapid edge wear. On the other hand, chips that are too thick will overload the cutting edge and cause it to chip or break.

Advanced software enables moldmakers to take advantage of newer cutting strategies such as hard milling, which employs smaller tools taking light, fast cuts. Many shops set up a machine to rough a component in its unhardened state, put the part through heat treatment then set it up again for finish-machining. Progress in tooling and programming software for hard milling now permits rough- and finish-machining of hardened parts in one setup, eliminating the time and effort spent in the initial setup for machining prior to hardening.

Optimized roughing is another software-based strategy that boosts productivity and at the same time extends tool life. Optimized roughing toolpath algorithms control tool engagement in real time. The toolpaths typically combine large axial depths of cut with small radial depths of cut, high feed per tooth, and high cutting speeds that shorten cutting times and increase metal-removal rates. In addition to providing greater throughput, advanced roughing strategies feature smooth cutting paths without rapid changes in direction or cutting parameters, reducing the load on the tool and significantly improving tool life.

Regarding the cutting tool technology element of the machining system, cutting tool suppliers are constantly developing new cutter geometries, substrates and coatings, such as end mills engineered for hard milling featuring coatings that can provide cutter life increases of 50 percent while adding minimally to cutting tool cost. The manufacturing tolerances of molds themselves are getting tighter. To better support milling of tighter tolerances, some end mill tolerances have improved from

10 microns to 5 microns on radius. New cutter geometries, substrates and coatings, combined with advanced software and long-reach, short-diameter tools, enable shops to machine small details that otherwise would require EDM.

In reality, cutting tool advances are driven as much by the moldmakers’ customers as by the moldmakers themselves. Years ago, a mismatch of 0.001 inch between mold cavities was essentially inconsequential. Today, a gap as small as 0.0002 inch in a silicon injection mold will produce flash. As a result, mold components must be machined to an even tighter tolerance to be acceptable. Increasingly strict mold specifications drive demand for cutting tools that provide long, consistent life and enable moldmakers to achieve and hold critical dimensions over extended periods of time.

To remain competitive, every shop must continually seek out new technologies and strategies, and weigh the worth of the advanced products and ideas relative to the shop’s particular operations. Manufacturers must continue to innovate or be left behind. Mold builders should make themselves aware of, and fully exploit, the product and application resources available to them from cutting tool, machine tool and software suppliers.

Increased manufacturing productivity and the strength of the North American economy are prompting some mold contracts to return from Asia or are enabling North American shops to win the contracts initially. Major reasons for the newfound moldmaking competitiveness are the combinations of tooling, machines and software that enable shops to run untended or minimally tended operations and overcome the labor cost advantages of suppliers overseas.

Related Content

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreRead Next

Maximize Hard Milling with Balanced Machining Process Factors

Successful application of high-speed milling of hardened steels requires an understanding of the many factors that influence the entire machining process.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.png;maxWidth=300;quality=90)