Capitalizing on a Packaging Niche

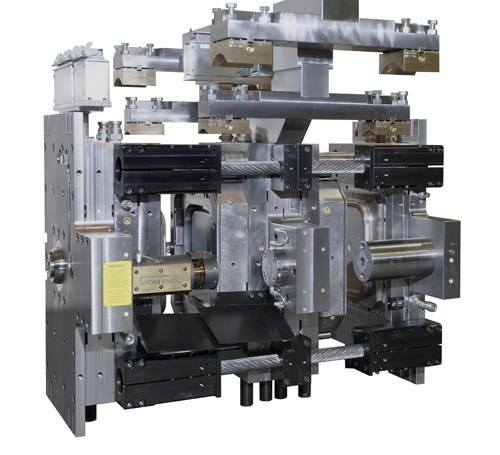

Top Grade Molds Ltd. (TGM; Mississauga, ON) has always been known for its thin-wall, open top molds for the industrial packaging market.

Share

Read Next

Top Grade Molds Ltd. (TGM; Mississauga, ON) has always been known for its thin-wall, open top molds for the industrial packaging market. Recently, the company made a strategic decision to further immerse itself in this market by delving into the caps/closures segment and become the source all things packaging. Forming an alliance with an independent agent (see Joining Forces Below) was key for this company to spread the word about its niche packaging expertise during tough economic times.

TGM Project Engineering and Marketing Manager John Plut emphasizes the company’s forté has been in packaging since its inception. “Our strength is technology,” Plut comments. “With more than 70 mold and product patents, we believe in investing in the future. We don’t try to compete with Asian markets. Our goal is to always push the envelope in packaging technology. We stress user- and business-friendly technology—technology that makes mold changes easier, cycles shorter and technology that can keep up with sustainability initiatives. With a complete core competency in the spectrum of packaging, TGM also offers complete hot runners and mold bases for any packaging application. Regardless, if the need is tamper-evident packaging or product design shifts from round to square, our technology patents target converters that want the latest mold ideas that will give them an edge moving forward—and gives them one number to call to get it.”

Thus, the decision to further penetrate this market by servicing the caps/closure segment seems to be a no-brainer. Nevertheless, TGM hired APTIGroup (Oakville, ON)—a sales agency with a wealth of knowledge and experience in the caps and closures market—to ensure it was in the best position possible to achieve success in this venture. “Our goal is to increase visibility in this area, for specialty type closures,” Plut says. “We can do the standard caps, but there are companies better suited and more geared toward it than us, so that’s not our focus. The market segment we wish to focus on is the flip top and specialty closures market—caps and closures that take a bit of effort and ingenuity to figure out. It’s that ingenuity that has been our strength in the open-top segment, and we want to continue that recipe for the closures market.”

Planning for Growth

TGM is fortunate in that it already had the core strength for this market expansion. “We technically didn’t need to add anything to the shop, only around it,” Plut says. “We believe the secret to success in moldmaking is remaining consistent in your growth plans. Growing beyond your means will leave your customers (new and old) left out hanging when something goes wrong.

“In that same vein, internal growth must match business growth,” Plut continues. “As a moldmaker your biggest strength is your people, your next biggest strength is the tools you house to utilize those people. Good people can’t help you if you have bad equipment. The most expensive mill or grinder is useless unless you have the right operator behind it. TGM’s core belief in sales is that technology is developed with our existing customer base in mind, not for the intention of attracting new clients. The inevitable result is the latter, but we believe in taking care of those that take care of us first. New customers that join our family quickly find that out—and the benefits to that philosophy become quickly evident.”

Enter APTIGroup. According to Plut, TGM had already established a rapport with the agency before the alliance was formed. “APTIGroup’s president, Fernando Segovia, was actually an employee of TGM in the early 90s, before he moved onto StackTeck to become the VP of Sales,” Plut explains. “There he developed and grew the business of caps and closures (along with all aspects of their packaging markets) with great success. He left that position to pursue and start APTIGroup, which has led him full circle back to representing TGM.

“It’s a symbiotic relationship, as TGM is very diverse in the open top packaging market, and with budding roots in closures, with global experience and exposure, APTIGroup is a natural fit to bring us to the next level,” Plut adds. “Experience is key, and they provide that. APTIGroup can provide a more complete solutions approach, in that they come in with full system proposals in both closure-type and IML open-top applications. They are no different than a sales agent in any other industry in how they represent us, but the difference with APTIGroup is they really know what they are doing—not just sales-wise—but in the application of what they are selling. This gives our customers an extra source to draw from.”

A Work In Progress

Plut is very pleased with TGM’s foray into the caps/closures market. “As a Canadian manufacturer, it is no secret that it has been a rough road for many companies and that Canadian manufacturing has taken a specific hit,” he states. “The rising Canadian dollar and decline in need has spelled the end for many a company—including some close competitors of TGM. Through all of that, we can proudly boast that we have grown. Our annual output has increased by almost 40 percent in the past four years.”

Predicted continued success with this venture has resulted in plans for TGM to expand its operations. “We have applied to the city for permits to connect our buildings, effectively adding 20 percent of office and manufacturing space,” Plut says. “Expansion plans are contingent on permits, but we are positive the improved business climate—coupled with our need to grow and expand physically—will drive us forward and make the expansion a reality.”

TGM President Vince Ciccone couldn’t agree more. “We are excited by this move,” Ciccone enthuses. “The APTIGroup alliance will allow our company to expand into new markets and add further diversification to our business model. Our company has always been committed to being a leader in providing innovative plastic tooling solutions to the industry. Our relationship with APTIGroup will enhance our ability to take advantage of our more than 70 tooling patents and to expand our target markets.”

Read Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More