Choose the Right Cutting Tool Strategy to Machine Efficiently and Affordably

A look at a couple current cutting tool technology trends: aluminum machining: face milling and mold steel machining: high-feed milling.

Today’s machining market demands efficiency and affordability and the moldmaking industry is no stranger to this. Moldmakers not only face a down economy, but also a competitive global market in which the parts that they need to machine, the machines used and the materials they are machining are becoming more complex.

With technology evolving rapidly, one might overlook the different offerings out in the marketplace. While carbide manufacturers change their geometries and upgrade their technology, a moldmaker has a variety of cutters to choose from for their application. Milling cutters vary from application specific to ones that can machine multiple materials and applications. Following is a look at a couple cutting tool technology trends, offerings and their applications and benefits.

Aluminum Machining: Face Milling

Today in moldmaking it is very common to see a manufacturer use aluminum material over steel for their plastic injection molds. Aluminum is easier to machine, easier to handle, able to provide quicker turnaround times, and in most cases, higher quality for their injection-molded plastic products. Aluminum still has its unique characteristics that require a different machining style than that of mold steel.

With the different choices in milling cutters and geometries, how do you know which cutter and geometry is right for your aluminum application? What geometry should I use? Which insert grade do I choose? Can I get more tool life than what I am already getting?

Tips for Machining Aluminum

Choosing the right geometry: In most aluminum applications we generally want to choose a sharp geometry that should shear material off, as supposed to machining with a honed edge that pushes the material off. High positive geometries decrease the cutting load and adhesion, while increasing the tool life of the insert.

Choosing the right insert grade: Aluminum likes to stick wherever it can. The right grade can make a difference in tool life and surface roughness. Choosing a coated insert, such as a standard CVD- or PVD-coated insert could create unnecessary edge build-up. A hard, uncoated insert with a mirror buffed finish could give you longer tool life. Many manufacturers offer this type of technology or something similar.

There are however coated inserts that are specifically made for non-ferrous materials. DLC (diamond like carbon) coatings and diamond coatings are both coated inserts that use coatings to extend tool life and improve surface roughness. Although these coatings are more costly, you can expect a better surface roughness and longer tool life—about two to four times for the DLC coating and about five to seven times the tool life with a diamond coating.

When the properly combined insert is chosen with the optimal geometry and grade, you can achieve longer tool life, very good surface roughness and less adhesion. With the proper machine and holding system, you can also maximize the indexable tool’s capabilities. Some cutters are even able to reach a speed above 4,000 surface feet per minute with uncoated carbide.

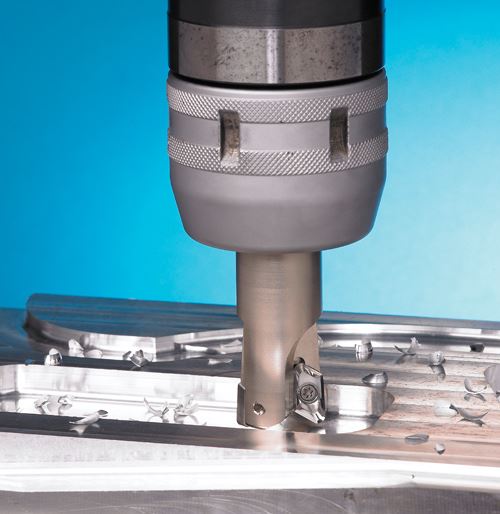

Mold Steel Machining: High-Feed Milling

How much metal are you removing and how fast are you removing it? A common question among mold shops today, which leads to the next topic: high-feed metal removal. High-feed cutters give you the advantage of machining efficiently and affordably. You can actually achieve a metal removal rate two to three times faster than a conventional mill. Many new CNC machines that are produced today are stronger and more powerful giving machinists the capability of using the high-feed technology.

High-feed milling normally uses several features in the carbide insert to achieve high efficiency. In the past many mold shops would use a round insert in milling applications. Recently, many companies manufacture inserts that can achieve higher feedrates compared to the traditional round insert. The insert’s characteristics are essential to successfully and safely achieve high-feed milling.

High-feed inserts usually have a strong geometry. Trigon shapes are commonly seen in high-feed mills. These inserts often display a large nose radius, a thicker insert size and an advantageous lesser approach angle (>45 degrees). The combination of these traits enables the machinist to apply a higher feedrate (with a smaller depth-of-cut)—in some instances as much as 0.118 inches per tooth on the milling cutter.

Several cutters on the market offer an even stronger double-side negative insert. These stronger double-sided inserts strengthen the inserts' capabilities. Negative milling inserts with a positive geometries are now a popular way of milling.

Common traits of a negative insert are that the inserts are normally thicker in size and have a positive geometry. Double-sided inserts are very beneficial. The first and most obvious reason is that you get double the usable corners on the insert (which is the trendy green thing to do); and, in addition to more usable cutting edges, inserts are now stronger. If used correctly a machinist can actually increase tool life with certain negative milling cutters. In certain designs of high-feed milling cutters, the negative styles have been known to actually reduce cutting force when compared to their single-sided relative.

Summary

In the ever-evolving world of mold manufacturing, productivity and efficiency is crucial to stay competitive. Choosing the right tool will allow you to use your machines’ full capabilities, providing today’s mold machinist with productivity and efficiency.

Related Content

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection, there are many variables that can dictate the best option for moldmaking.

Read MoreVIDEO: Qualifying Modified H-13 for 3D-Printed Tooling

Next Chapter Manufacturing and International Mold Steel discuss their partnership to qualify a modified H-13 for tooling applications.

Read MoreProject Reveals Added Benefits of New P20 Grade Steel in Machinability, Cycle Time and No Stress Relief

MoldMaking Technology's Christina Fuges talks with General Motors' Shane Appel about a project testing a new P20 steel grade's dimensional stability.

Read MoreQualified Tool Steel Enhances Thermal Transfer, Long Tool Life

Next Chapter Manufacturing has successfully qualified HTC-45 tool steel, an optimized version of H13, to support better thermal transfer and faster cycle times for molders and die-casters.

Read MoreRead Next

Considerations for a High-Feed Milling Strategy

High-feed milling is becoming the chosen methodology for removing as much material as possible in the shortest amount of time, as more shops equip themselves with high-speed CNC machining capability and sophisticated CAM programs.

Read MoreThe Common Ground Between Moldmaking and Aerospace

Many of the proven technologies used for mold and die machining can also be used in difficult to machine aerospace materials.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)