MMT Blog

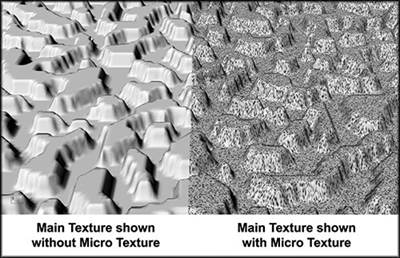

Understanding Texture Repair

Developing a texture repair plan will help get a damaged mold up and running.

Read MoreIs Your Concept of Production Costing You Money?

Common misconceptions about aluminum tooling may affect your next mold material selection.

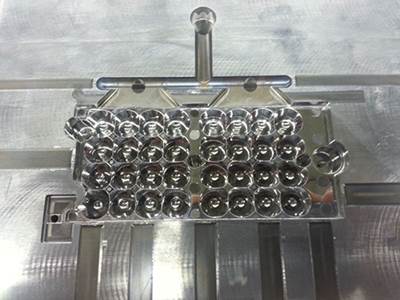

Read MoreBuilding a Mold in Fewer Setups

Current machine tool technology can reduce complex elements of moldmaking while increasing mold quality and accuracy.

WatchIn the Trenches: How Not to Troubleshoot, Part 2

Lessons learned when a legitimate corrective action is not performed.

Read MoreMoldmaking Opportunities in NAFTA Markets

North America contains the two largest trading partners for the U.S. plastics industry—Mexico and Canada. In 2012, these two countries were the destination for $13.6 billion and $12.5 billion worth of U.S. plastics industry exports, respectively. Combined, this represented 31 percent of total U.S. plastics industry exports in 2012.

Read MoreMoldmaking Hits Michigan

Southeastern Michigan is an active mold manufacturing area, and amerimold expo 2014 is headed back to take advantage of all that activity for exhibitors and attendees alike.

Read MoreMoldmaker Awarded for Its Job Creation Efforts

After a busy year of expansion, one low-volume injection molder/moldmaker is recognized for its dedication to job creation.

Read MoreDMG MORI Unveils 8 New Machines

Larger work envelopes, enhanced cooling capability and improved energy efficiency are among the features the new models have in common.

Read MoreBeing Versatile

Once you acknowledge the importance of detecting errors early in the design process, you can begin to look for technology to help you accomplish that goal. That is exactly what Versatile Mold and Design did when it started using a laser scanner and inspection software to verify its electrodes.

Read MoreTreating People Right

This mold shop’s atypical approach to management is, in part, a reflection of its drive to provide a work environment that employees are happy to return to day after day.

Read MoreEngineer, Build, Maintain Is Back!

With less expertise available, and OEMs and tier suppliers employing fewer technical engineers, they are more reliant on their supply chain for that expertise. With that in mind, the 2014 amerimold technical conference will continue its three-track program to tackle these challenges with a focus on Engineer, Build and Maintain.

Read More