Tool Steel

May MMT Digital Edition Available

This month we take a look at how to define mold steel toughness, a new roughing strategy that helps maximize metal removal rates and reduce roughing cycle times, enhanced metrology technologies, electrode material selection, women impacting moldmaking, and much more.

Read MoreDefining Mold Steel Toughness

Consider grades that have undergone the electroslag remelting process.

Read MoreSLIDESHOW: Technology Showcase – Mold Materials

Tool steel, aluminum, copper and alloys are some of the materials used to manufacturing molds, and the choice of materials to use is critical to the overall performance of the mold.

Read MorePVD Coatings and Tool Steel Selection

Mold users are driving an increased use of physical vapor deposition (PVD) coatings, and this has generated questions and concerns from mold builders as they select materials from which to manufacture their molds. PVD coatings are a family of very thin (approximately 2 to 5 microns) metal layers applied in a vacuum chamber using a plasma process.

Read MoreLooking for a Tool Steel Heat Treatment Source?

How does agitating a quench liquid improve quenching speed? Why do tool steels require a high austenization temperature for hardending? How thick can a P20 mold steel be through hardened into the center? These and other questions were answered during last week's webinar on heat treatment basics.

Read MoreCutter Sets New Standard for Heavy Hogging

A recent roughing application shattered this moldmaker’s expectations about the stability of a large face mill in long-reach contouring operations.

WatchCryogenic Basics

Cryogenic machining technology milling fluid end component made of 4340 high alloy hardened steel.

WatchThe Potential of Enhanced Venting Materials

Stop fighting venting problems with mold retrofits and prevent them by designing the original mold with an enhanced venting steel.

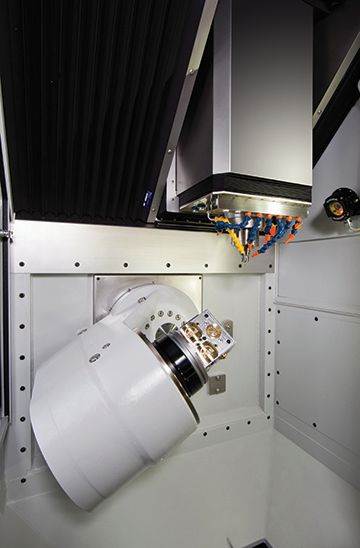

Read MoreProductivity Meets Precision

With machine dynamics, mechanical design and thermal stability in control, mold manufacturers can take five-axis machining to the next level.

WatchGet Schooled on Mold Material Selection

The evolution of pre-hardened mold steels was presented during the "Global Advances in Pre-hardened Mold Steels" webinar by International Mold Steel last month, and audience members walked away learning these five facts about mold steels.

Read More