Tool Steel

Celebrating a Solution for a Sticky Situation

In MMT we focus a lot on surface treatment challenges and solutions, so this little tidbit caught my attention. Life changed 60 years ago for a man selling steel to mold builders when the need for "unsticking" plastic parts from molds revealed an opportunity for a new product--silicone oil in an aerosol can. This evolved into the first mold release – and foundation – of the new Percy Harms Corporation, predecessor of Slide Products, which celebrates its 60th anniversary in the injection molding industry this year.

Read MoreIt All Starts with the Steel…

Those were the words spoken by Tim Nealt, Vice President Sales, of steel supplier A. Finkl and Sons, as he and Mold Steel Product Manager Todd Gilhuly guided me and several of my colleagues on a tour of their new 44-acre facility earlier this week.

Read MoreSteel Price Outlook: Firm in 2013, Moderately Higher in 2014/2015

The rising cost of mold steel will be a problem for many North American moldmakers in the short term, but it will also generate many opportunities for moldmakers as substitutes for steel parts are developed in industries such as autos, appliances, medical, and aerospace.

Read MoreLinear Five-Axis at Die Tech & Engineering

Video about using linear motor 5-axis machines at Die Tech & Engineering in Wyoming Michigan near Grand Rapids. Simultaneous five axis contour milling of hardened tool steel.

WatchThree Stories to Watch This Summer

For the past few years, North American moldmakers have been vigorously engaged in trying to cope with three industry-wide problems. These are: low-cost competition from China; a shortage of qualified workers entering the trade; and the rising costs of materials (i.e. tool steel) and labor (i.e. healthcare costs). These problems are far from solved. The future is far from certain. And moldmakers will continue to struggle with these issues for the foreseeable future. But just in case you are getting bored or uninspired with the challenges posed by these issues, here are three more storylines that will unfold this summer and which merit your attention.

Read MoreTool Steel and Aluminum Staying Strong

A roundtable of mold material suppliers discuss how new offerings result in easier machinability, better weldabilty, increased strength and improved surface hardness.

Read MoreClosest to the Pin Contest at PCS Booth #2571

Enter to WIN A FREE: Aluminum Mold Base, Stainless Steel Mold Base, platen GUARD™ Locating Rings.

Read MoreVacuum Heat Treating of Tool Steels

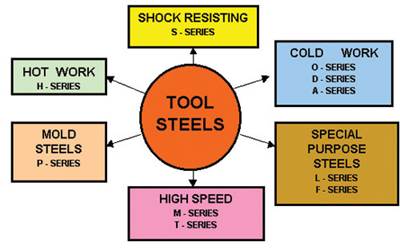

Tool steel refers to a variety of carbon and alloy steels that are particularly well-suited to be made into tools, however, special attention needs to be paid during their heat treatment so as to achieve the best properties for a given application.

Read MoreCutting to the Core of Medical Molds

Hard milling intricate steel geometry for critical medical devices cuts to the core of suppler relationships.

Read More