Tool Steel

Alro Steel Starts Construction

Alro Steel starts construction of a facility in Oshkosh, Wisconsin.

Read MoreCVD-Coated Cutters Enhance Steel Turning Performance

Tungaloy’s new T9225 insert grade complements the T9200 CVD Grade Series for steel turning.

Read MoreHow to Avoid Tool Steel Corrosion

A mold builder should consider corrosion resistance, hardness, machinability, processing, polishability, operational environment and wear resistance during tool steel selection.

Read MoreSteel Resists Wear from Abrasive Resins, Extends Tool Life

DC53 is a fully hardenable mold steel from International Mold Steel that withstands wear from abrasive resins.

Read MorePre-Hardened Steel Designed for Machinability

Hasco’s 1.2714HH pre-hardened steel supplements its plate lineup and offers optimum wear resistance, stability and other properties for machining.

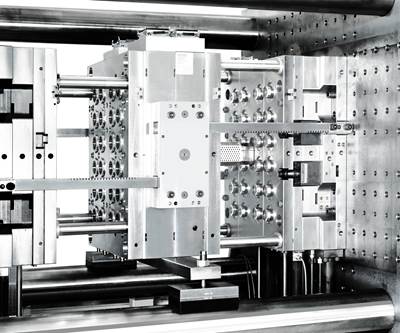

Read MoreGear Unit for Stack Molds Increases Output and Precision

With so much happening in a busy show year between NPE2018, Amerimold 2018 and IMTS 2018, MoldMaking Technology is revisiting some of the technology that was on display. In case you missed it: Meusburger’s gear unit for stack molds doubles output capacities while also offering higher precision and stability. The company had the gear unit on display at Amerimold 2018.

Read MoreModified Remelting Process Improves Material Purity

Edro says that M333 Isoplast is produced using an optimized chemistry, a modified production process and the latest steel re-melting technology known as Pressure Electroslag Remelting (PESR).

Read MoreTechnical Specialist Helps Customers Choose Ideal Alloy

Technical representatives from Ellwood Specialty Steel are available to assist customers in choosing the most suitable aluminum or aluminum alloy for a given mold project.

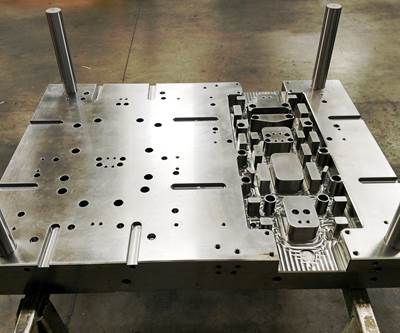

Read MoreMold Steel Composition Streamlines Moldmaking Process

A mold material’s performance characteristics, like uniform hardness and dimensional stability, enabled Dramco Tool Co. Inc. to build a compression mold faster and more economically.

Read More