Looking for a Tool Steel Heat Treatment Source?

How does agitating a quench liquid improve quenching speed? Why do tool steels require a high austenization temperature for hardending? How thick can a P20 mold steel be through hardened into the center? These and other questions were answered during last week's webinar on heat treatment basics.

Share

How does agitating a quench liquid improve quenching speed? Why do tool steels require a high austenization temperature for hardending? How thick can a P20 mold steel be through hardened into the center? These and other questions were answered during last week's webinar on heat treatment basics.

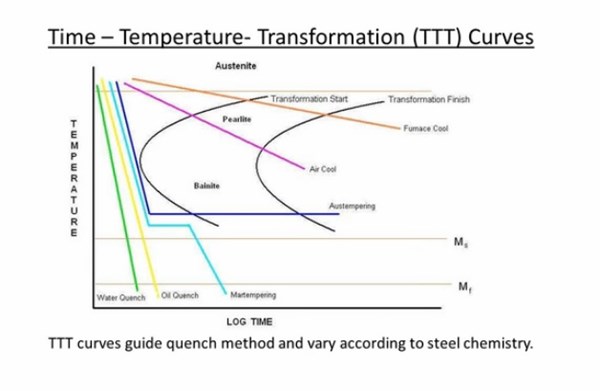

Mold and die steels can be supplied pre-hardened or in a soft condition to facilitate machining. If machined soft, the steel must be hardened to enable the material to withstand the demands of a production environment. Heat treatment is the process for hardening or altering the internal structure of steels. Several processes can be used to achieve the desired end condition. Once considered an art, heat treatment has been refined by science and technology to a reliable and repeatable industry.

Click here for our archived webinar presented by Ellwood Specialty Steel.

Related Content

-

What You Should Consider When Purchasing Modified P20 Steel

When buying P20 steels that have been modified, moldmakers must be aware of the variations and key issues that affect delivery, cost and lead times.

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

-

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.