Tool Steel

Material Matters

Hardness, machinability and strength are the bottom line as materials manufacturers and suppliers continue to reduce moldmakers’ leadtimes without sacrificing quality or cost.

Read MoreTooling Board Features Excellent Dimensional Stability, Easy Cutting

This EB6200 high-temperature epoxy tooling board—developed by BCC Products Inc./Blehm Plastics (Franklin, IN)—was built for the composites industries.

Read MoreIs It Still Time to Reach for a Die Profiler?

Pointers for bringing a polished surface to a high mirror finish. You have finished machining your mold core and cavity and removed them from your CNC machine. The mold components are machined in tough H-13 steel and contain several deep grooves and slots that must be properly polished to allow the molded part to eject. What is the best method for bringing the polished surface to a high mirror finish?

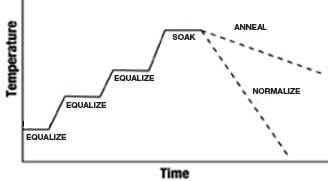

Read MoreTool Steel and Heat Treatment, Part 2

Tool steel, its classification, heat treatment and how to consider manufacturing methods in relation to heat treatment and the metallurgy of heat treatment.

Read MoreBridging the Gap between Prototyping and Final Steel Production Tooling

SL modeling and rapid tooling methods combine to produce durable epoxy injection molds that generate production-quality parts in record time.

Read MoreGas Permeable Mold Steel

The use of venting material in appropriate areas can eliminate gas buildup, reduce injection pressure, lower cycle times, gloss levels and substantially reduce scrap and reject rates.

Read MoreA Machine Cuts Carbon and Hard Steel at 60 Percent of the Cost

The right high-speed machining center and software helps one mold builder turn an important corner in mold building productivity.

Read MoreHow to Select the Right Steel Grade to Improve Mold Performance

A look at an improved steel grade utilizing boron metallurgy that will help shops reduce internal costs and minimize the risk of failure during manufacturing.

Read MoreTool Steel and Heat Treatment, Part 1

An introduction to heat treatment for the moldmaker.

Read MoreChoosing the Right Aluminum Alloy for Production Injection Molds

Aluminum may be a better solution than steel after a thorough review of part design, tool design, quantity and type of unfilled, aluminum-friendly resin.

Read More